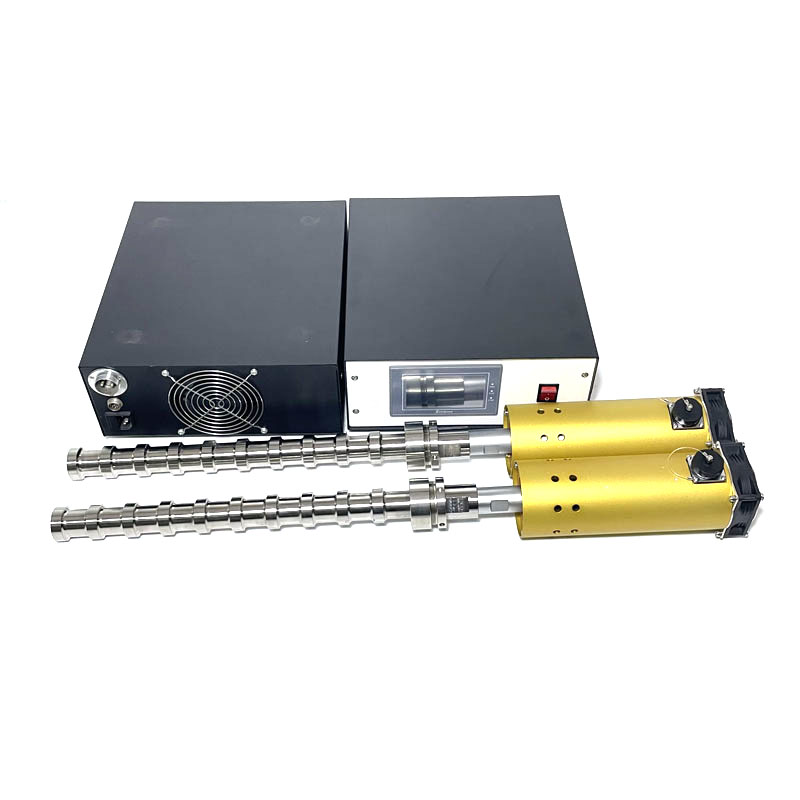

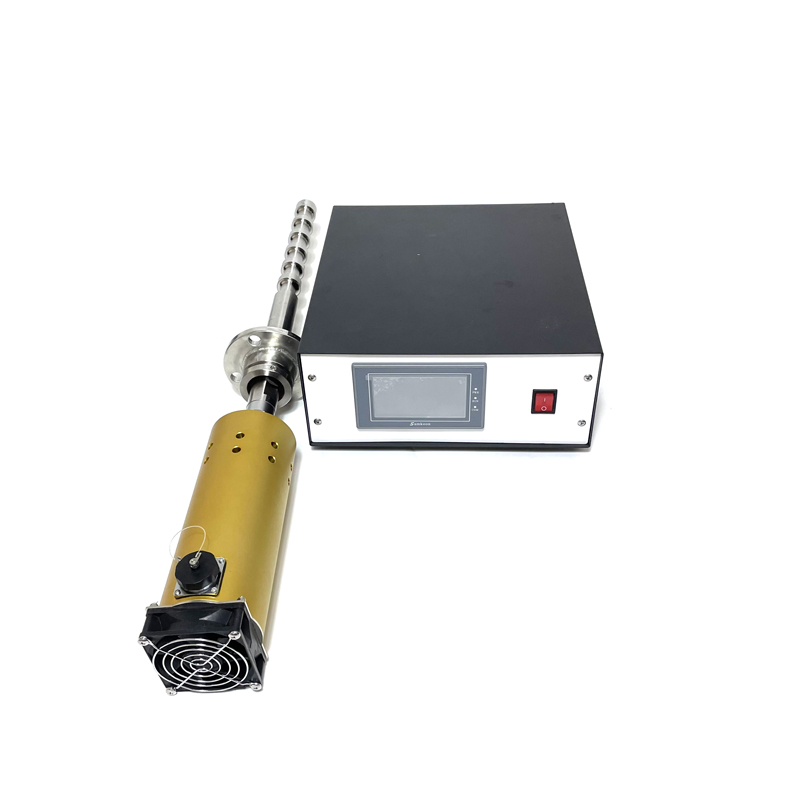

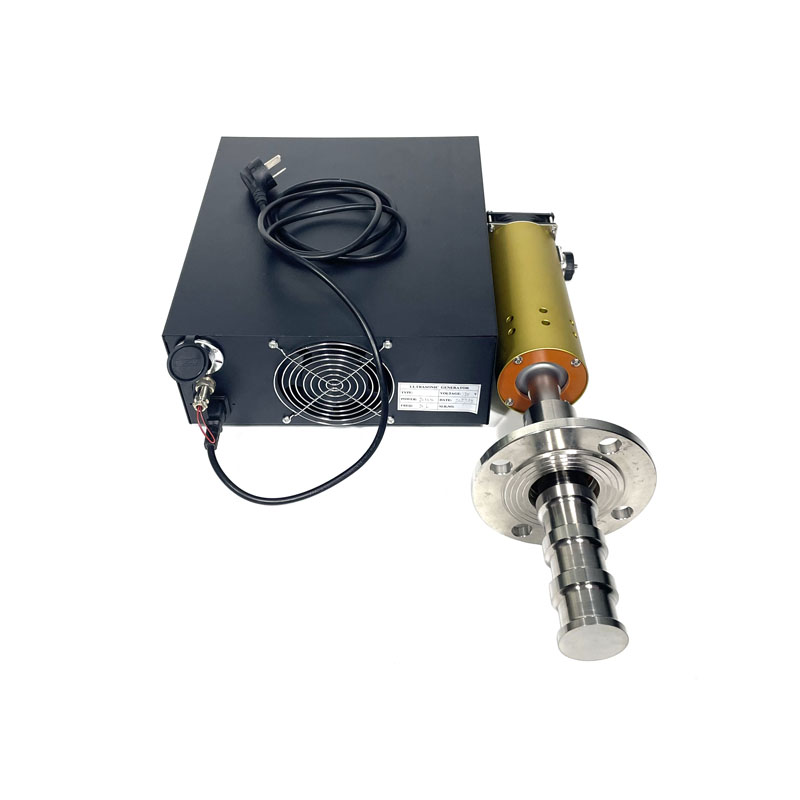

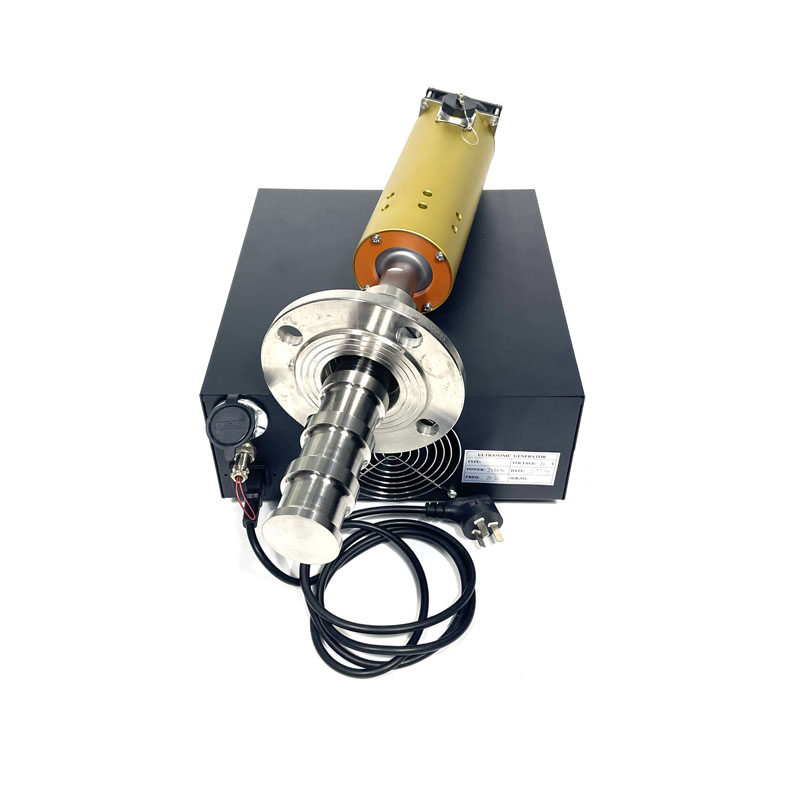

20KHZ 1800W 220V Ultrasonic Sonochemistry Reactor Ultrasonic Assisted Extraction Method

Characteristics of ultrasonic sonochemical treatment equipment: Cavitation is generated around the ultrasonic vibrating rod, and the ultrasonic energy is very uniformThe distribution in the tank achieves the cleaning effect. The power output of the ultrasonic vibration rod is not affected by loads such as liqui…

20KHZ 1800W 220V Ultrasonic Sonochemistry Reactor Ultrasonic Assisted Extraction Method

Characteristics of ultrasonic sonochemical treatment equipment:

- Cavitation is generated around the ultrasonic vibrating rod, and the ultrasonic energy is very uniform

The distribution in the tank achieves the cleaning effect.

- The power output of the ultrasonic vibration rod is not affected by loads such as liquid level, tank capacity, and temperature difference

The impact of changes ensures stable and uniform power output.

- Due to the structural characteristics of ultrasonic vibration rods, their application range surpasses traditional ultrasonic vibration

The board is relatively wide and suitable for vacuum/pressure cleaning, as well as various chemical treatments

During the process.

- Ultrasonic vibration rods have a service life of more than 1.5 times that of traditional ultrasonic vibration plates.

- The circular tube design is flexible and easy to install.

- Basically ensuring complete waterproof sealing.

Scope of application of ultrasonic sonochemical treatment equipment:

Ultrasonic sonochemical processing equipment is used for workpiece cleaning in various industries, such as precision electronic zero

Parts, clock and watch parts, optical glass parts, hardware and mechanical parts, jewelry accessories, semiconductor silicon

Cleaning of chips, polyester filter elements/spinnerets, instruments, etc., and cleaning of parts before and after electroplating.

Ultrasonic extraction has the advantages of low extraction temperature, high extraction rate, and short extraction time

Used for material extraction, oil extraction, and effective content extraction of various animals and plants, it is an alternative to traditional methods

The shearing process method is a modern, energy-saving, and environmentally friendly means of extraction.

The superiority of ultrasonic extraction of materials is based on the physical properties of ultrasound, mainly

Reduce the target extract and sample base by generating fast mechanical vibration waves through piezoelectric transducers

The force between the bodies enables solid-liquid extraction separation.

| Tubular EquipmentType | Tubular TransducerType | Frequency(KHz) | UltrasoundOutput(W) | Total Length(mm) | Diameter(mm) | Static Capacity(pF±10%) |

| PU-UE1 | US-61 | 15-28 | 1000 | 500 | Φ50-55 | 68000 |

| PU-UE5 | US-25 | 15-28 | 1500 | 850 | Φ50-55 | 68000 |

| PU-UE6 | US-16 | 15-28 | 2000 | 1100 | Φ50-55 | 132000 |

20KHZ 1800W 220V Ultrasonic Sonochemistry Reactor Ultrasonic Assisted Extraction Method

标签:20KHZ 1800W 220V Ultrasonic Sonochemistry Reactor, Ultrasonic Assisted Extraction Method

Send Inquiry

Ultrasonic Vibration Reactor Cream Emulsify Homogenizer Mixing Machine And Ultrasonic Power Generator

Ultrasonic Vibration Reactor Cream Emulsify Homogenizer Mixing Machine And Ultrasonic Power Generator 1200W 20KHZ Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor With Signal Generator

1200W 20KHZ Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor With Signal Generator Ultrasonic Flow Through Reactors Ultrasonic Liquid Processor Ultrasonic Emulsify Machine Homogenizer

Ultrasonic Flow Through Reactors Ultrasonic Liquid Processor Ultrasonic Emulsify Machine Homogenizer 1000W 20KHZ Ultrasonic Emulsifier Mixer Homogenizer Ultrasonic Extraction Reactor

1000W 20KHZ Ultrasonic Emulsifier Mixer Homogenizer Ultrasonic Extraction Reactor 2400W Ultrasonic Emulsifier Mixer Homogenizer For Batch Extraction/Homogenisation

2400W Ultrasonic Emulsifier Mixer Homogenizer For Batch Extraction/Homogenisation 300W 20KHZ Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel And Sound Generator

300W 20KHZ Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel And Sound Generator 20KHZ 300W Titanium Alloy Anti-corrosion Biodiesel Ultrasonic Herbal Extraction Machine

20KHZ 300W Titanium Alloy Anti-corrosion Biodiesel Ultrasonic Herbal Extraction Machine Ultrasonic Oil Extractor Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer Liquid Processor

Ultrasonic Oil Extractor Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer Liquid Processor Ultrasonic Emulsification Disperser Cosmetic Mixing Extraction Ultrasonic Extraction Equipment

Ultrasonic Emulsification Disperser Cosmetic Mixing Extraction Ultrasonic Extraction Equipment 20L 2000W Ultrasonic Glass Reactor Ultrasonic Biodiesel Reactor And Frequency Generator With Digital Generator

20L 2000W Ultrasonic Glass Reactor Ultrasonic Biodiesel Reactor And Frequency Generator With Digital Generator Ultrasonic Sonochemistry Cell Diffusion Emulsion Industrial Ultrasonic Sonochemical Equipment

Ultrasonic Sonochemistry Cell Diffusion Emulsion Industrial Ultrasonic Sonochemical Equipment Ultrasonic And Microwave Combined Chemical Reactor Prices For School Laboratory Equipment

Ultrasonic And Microwave Combined Chemical Reactor Prices For School Laboratory Equipment