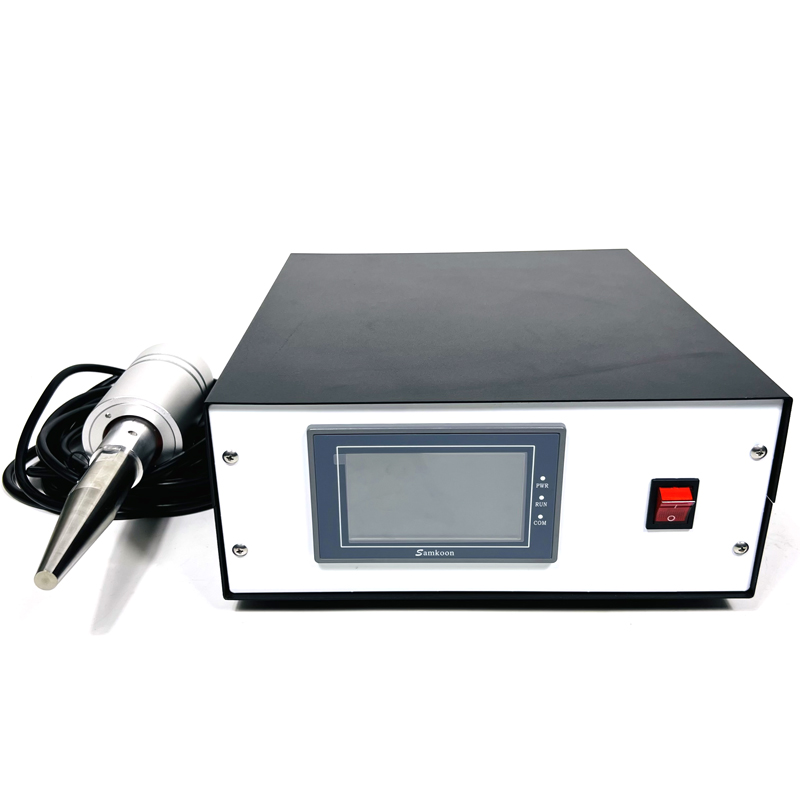

200W Industrial Ultrasonic Anti-Scaling/Descaling Machine For Oilfield Heat Exchanger

Principle of ultrasonic descaling Cavitation effect:The radiation of ultrasound can directly generate a large number of small bubbles in the processed liquid medium, which means that the liquid is pulled apart to form countless tiny local holes. When these holes and bubbles rupture and compress, a certain range of…

200W Industrial Ultrasonic Anti-Scaling/Descaling Machine For Oilfield Heat Exchanger

Principle of ultrasonic descaling

- Cavitation effect:

The radiation of ultrasound can directly generate a large number of small bubbles in the processed liquid medium, which means that the liquid is pulled apart to form countless tiny local holes. When these holes and bubbles rupture and compress, a certain range of strong pressure peaks are generated, with local pressure peaks reaching thousands of atmospheres. Under the action of the pressure peak, the scaling substance is crushed and suspended in water, causing the produced scale layer to break and fall off, achieving the purpose of scale removal.

- Activation effect:

Ultrasonic waves enhance the activity of flowing liquids and scaling substances through the “cavitation” effect in liquids, disrupting the conditions for scale production and deposition on pipe walls, allowing scaling substances to form dispersed deposits in the liquid instead of forming hard scales on the pipe wall, achieving the goal of scale prevention.

- Shear effect:

When ultrasonic waves propagate inward from the outer surface of the metal of the scaling heat exchanger, they will cause the scale on the metal heat exchange interface to vibrate with the metal. However, due to the different properties and elastic impedance of the scale and metal, asynchronous vibrations are generated, and they move at high speeds relative to each other. Due to the speed difference, relative shear stress is formed at the scale and metal heat exchange interface, leading to fatigue, cracks, fragmentation, and detachment of the scale layer on the interface.

- Inhibition effect:

By altering the physical and chemical properties of the liquid body through the action of ultrasound, it can inhibit the nucleation and growth of ions in water at the wall. Therefore, reduce the number of scaling ions adhering to the heat exchange surface. Practical research has shown that the longer the ultrasonic action time, the better the effect of preventing scaling substances from scaling. In short, under the action of ultrasound, water can generate short, local, extremely high temperature, high pressure, and strong electric field extreme physical environments in the conductive medium under ambient conditions of room temperature and pressure when the ultrasonic energy is large enough. The liquid will produce the so-called “acoustic cavitation effect”, leading to many mechanical, physical, chemical, biological and other effects, achieving the purpose of preventing and removing scale in the liquid.

| Model | Power | Frequency | Weight |

| PLS-CG200W | 200W | 15-20KHZ | 20KG |

200W Industrial Ultrasonic Anti-Scaling/Descaling Machine For Oilfield Heat Exchanger

标签:200W Industrial Ultrasonic Anti-Scaling, Ultrasonic Anti-Scaling/Descaling Machine For Oilfield Heat Exchanger

Send Inquiry

800W 20KHZ Ultrasonic Pulse Scale Inhibitor Descaling Anti-Scaling Machine With Ultrasonic Generator

800W 20KHZ Ultrasonic Pulse Scale Inhibitor Descaling Anti-Scaling Machine With Ultrasonic Generator 200W Industrial Ultrasonic Anti-Scaling/Descaling Machine For Oilfield Heat Exchanger

200W Industrial Ultrasonic Anti-Scaling/Descaling Machine For Oilfield Heat Exchanger 20KHZ 200W Ultrasonic Anti-Scaling/Descaling Machine For Oilfield Evaporator

20KHZ 200W Ultrasonic Anti-Scaling/Descaling Machine For Oilfield Evaporator 1000W 20KHZ Flowing Liquid Ultrasonic Descaling Anti-Scaling Machine With Ultrasonic Generator

1000W 20KHZ Flowing Liquid Ultrasonic Descaling Anti-Scaling Machine With Ultrasonic Generator Industrial Ultrasound Descaling & Anti-Scaling Equipment Digital Ultra Sonic Descaling Machine

Industrial Ultrasound Descaling & Anti-Scaling Equipment Digital Ultra Sonic Descaling Machine Industrial Ultrasonic Anti-Scaling/Descaling Machine For Magnetization Method Circulating Cooling Water

Industrial Ultrasonic Anti-Scaling/Descaling Machine For Magnetization Method Circulating Cooling Water 3000W 20KHZ Ultrasonic Metal Descaling Anti-Scaling Equipment And Ultrasonic Generator

3000W 20KHZ Ultrasonic Metal Descaling Anti-Scaling Equipment And Ultrasonic Generator Ultrasonic Pulse Ternary Composite Flooding Oil Well Pipeline Ultrasonic Descaling Anti-Scaling Equipment

Ultrasonic Pulse Ternary Composite Flooding Oil Well Pipeline Ultrasonic Descaling Anti-Scaling Equipment 3000W 20KHZ Ultrasonic Pipeline Descaling Equipment Ultrasonic Heat Exchanger Cleaning Machine

3000W 20KHZ Ultrasonic Pipeline Descaling Equipment Ultrasonic Heat Exchanger Cleaning Machine Ultrasonic Intelligent Antiscaling And Descaling Devices For Heat Exchanger Ultrasound Anti-Fouling System

Ultrasonic Intelligent Antiscaling And Descaling Devices For Heat Exchanger Ultrasound Anti-Fouling System Ultrasonic Pulse Ternary Composite Flooding Oil Well Pipeline Ultrasonic Descaling Anti-Scaling Equipment

Ultrasonic Pulse Ternary Composite Flooding Oil Well Pipeline Ultrasonic Descaling Anti-Scaling Equipment External Pipeline Ultrasonic Descaling And Anti Scaling Equipment And Ultrasonic Generator

External Pipeline Ultrasonic Descaling And Anti Scaling Equipment And Ultrasonic Generator