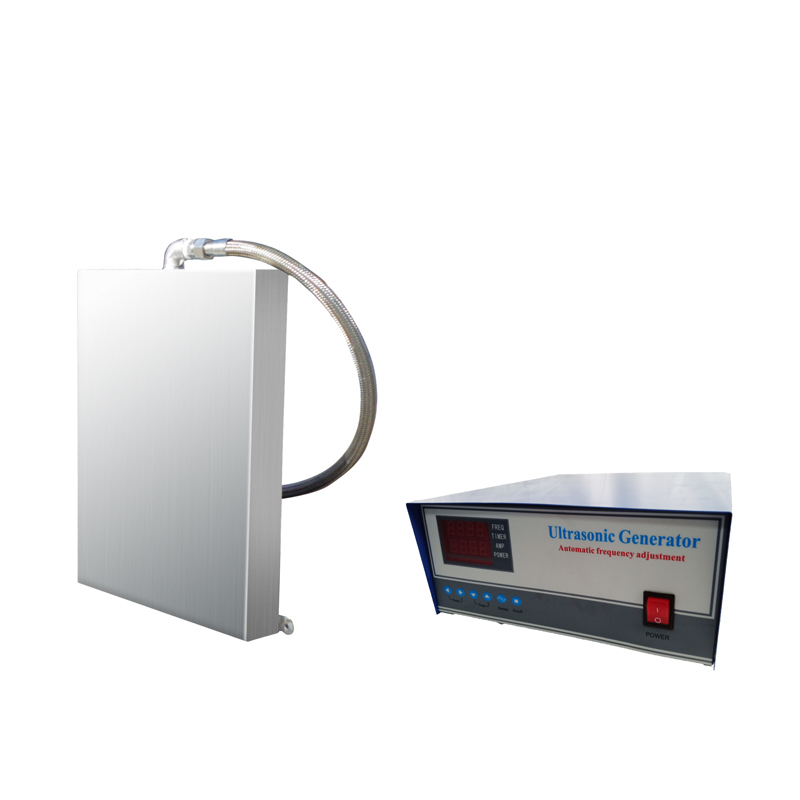

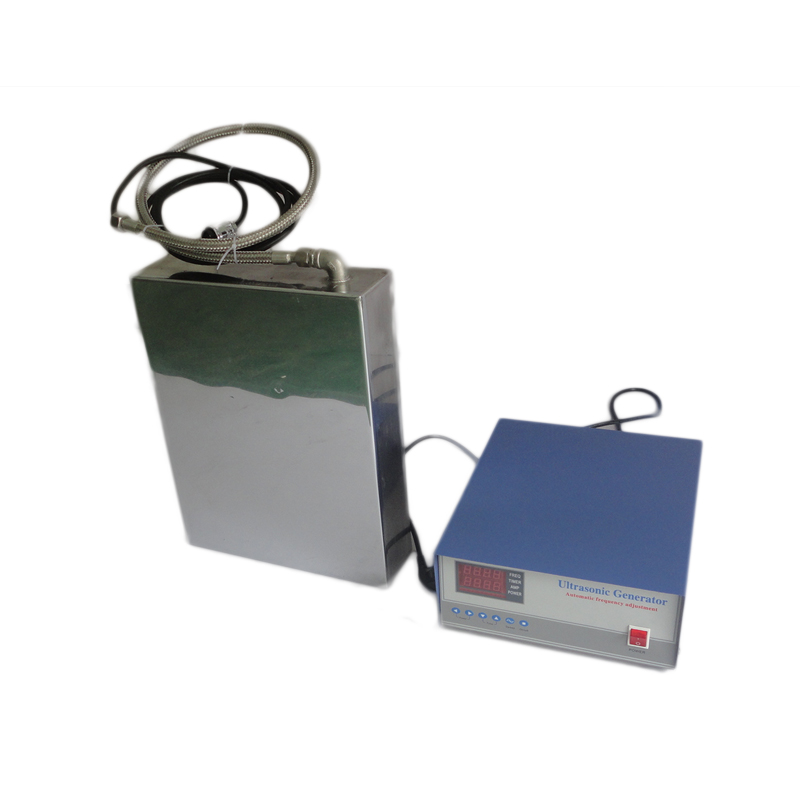

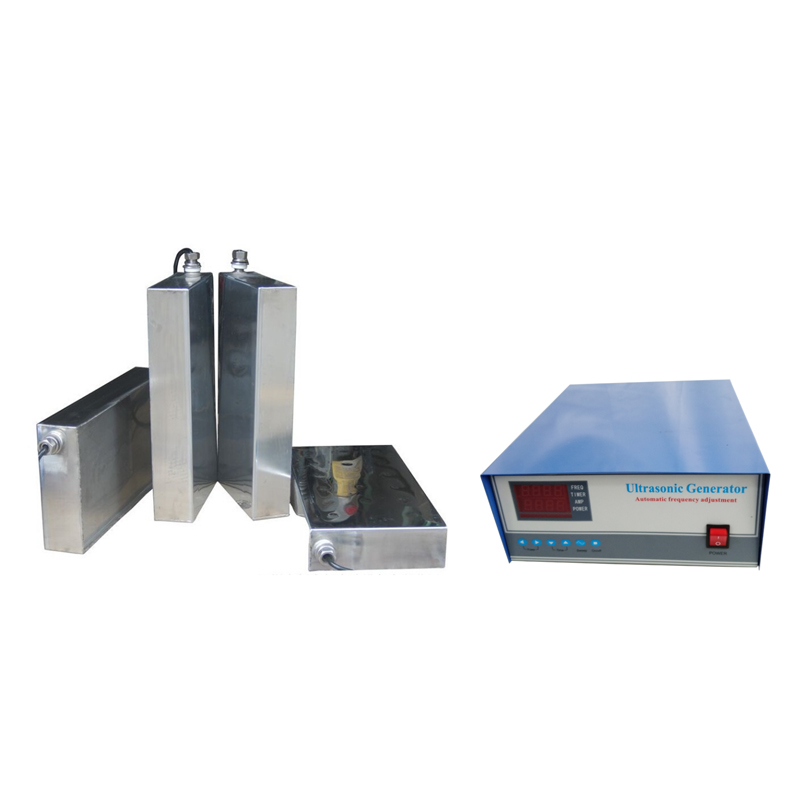

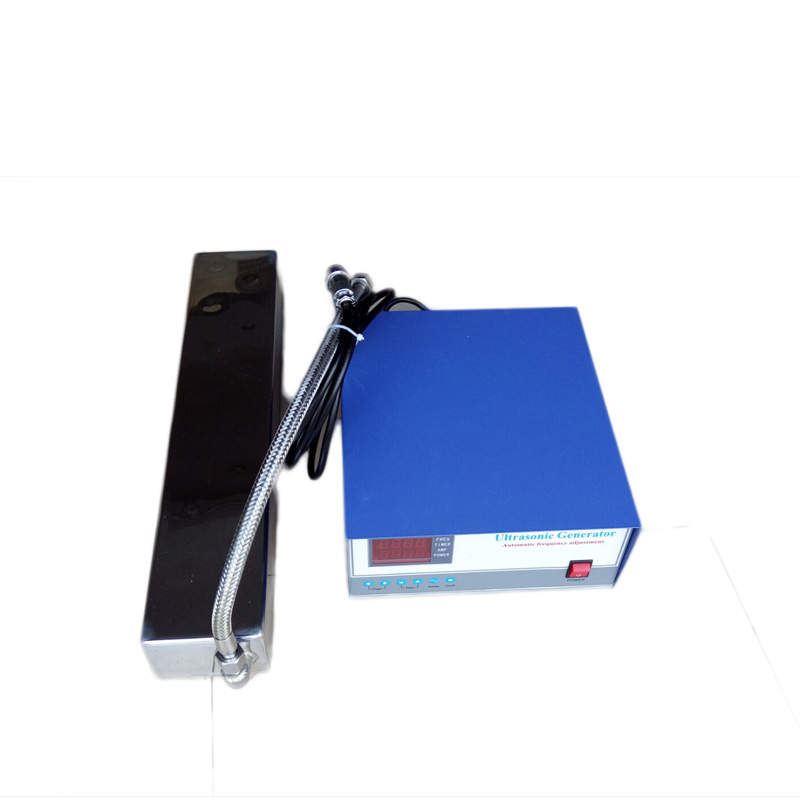

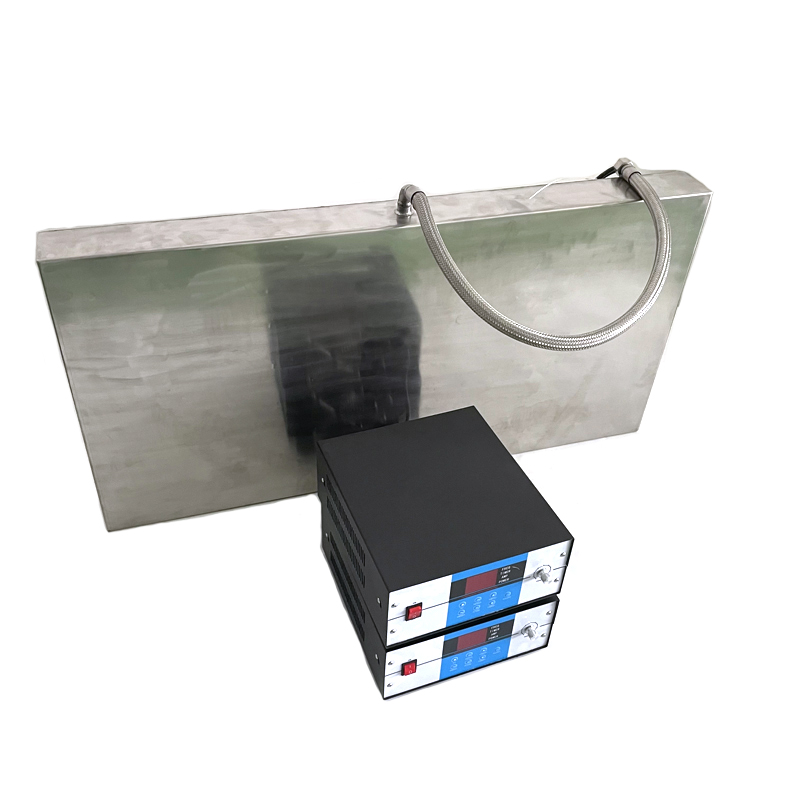

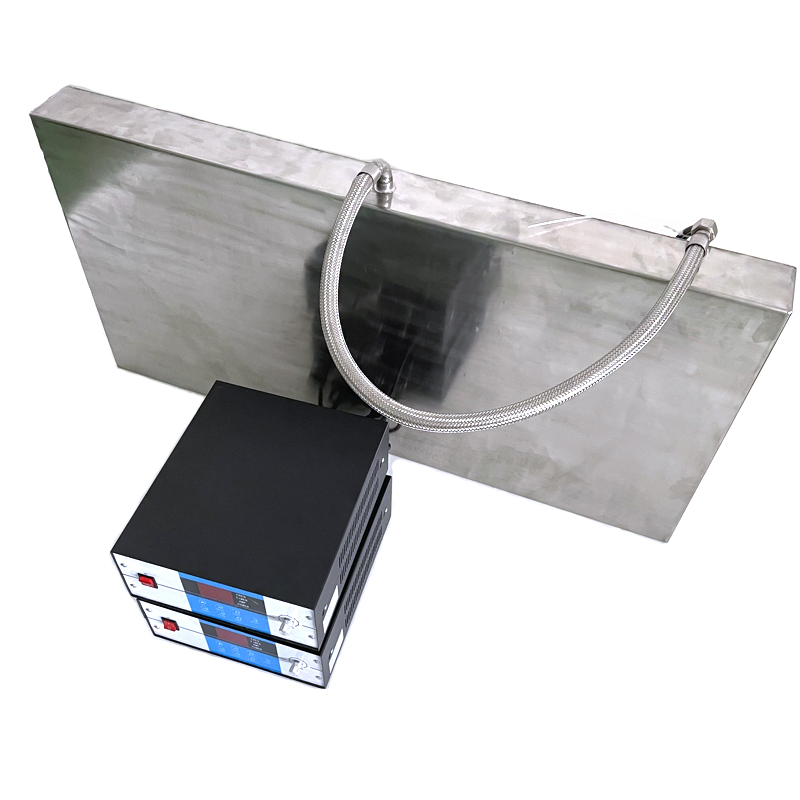

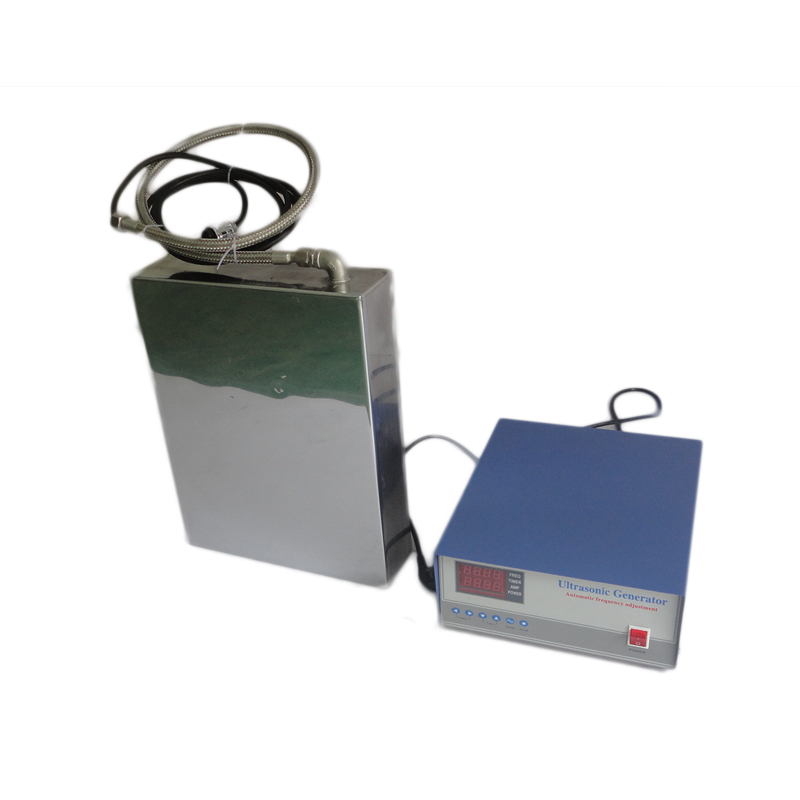

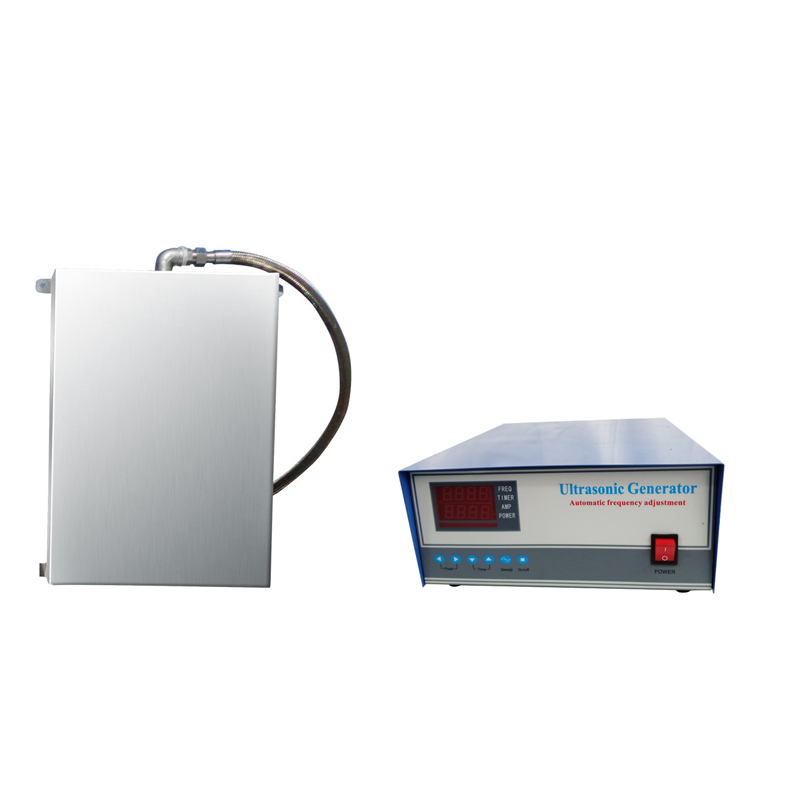

2000W Submersible Type Ultrasonic Cleaning Transducer And Frequency Generator For Cleaner Parts

The application principle of the ultrasonic vibration plate is that the high-frequency oscillation signal sent by the Ultrasonic Generator is converted into high-frequency mechanical oscillation through the transducer and transmitted to the medium. The forward radiation of the ultrasonic wave in the cleaning solvent …

2000W Submersible Type Ultrasonic Cleaning Transducer And Frequency Generator For Cleaner Parts

The application principle of the ultrasonic vibration plate is that the high-frequency oscillation signal sent by the Ultrasonic Generator is converted into high-frequency mechanical oscillation through the transducer and transmitted to the medium. The forward radiation of the ultrasonic wave in the cleaning solvent in the cleaning solution makes the liquid flow and generate tens of thousands of tiny bubbles. The tiny bubbles (cavitation nuclei) in the liquid vibrate under the action of the sound field. When the sound pressure reaches a certain value, the bubbles grow rapidly, Then it is suddenly closed. When the bubble is closed, a shock wave will be generated, and thousands of atmospheric pressures will be generated around it. The insoluble dirt will be destroyed and dispersed in the cleaning solution. When the group particles are wrapped in oil and adhere to the surface of the cleaning part, the oil will be emulsified and the solid particles will be separated, so as to achieve the purpose of cleaning the surface of the cleaning part.

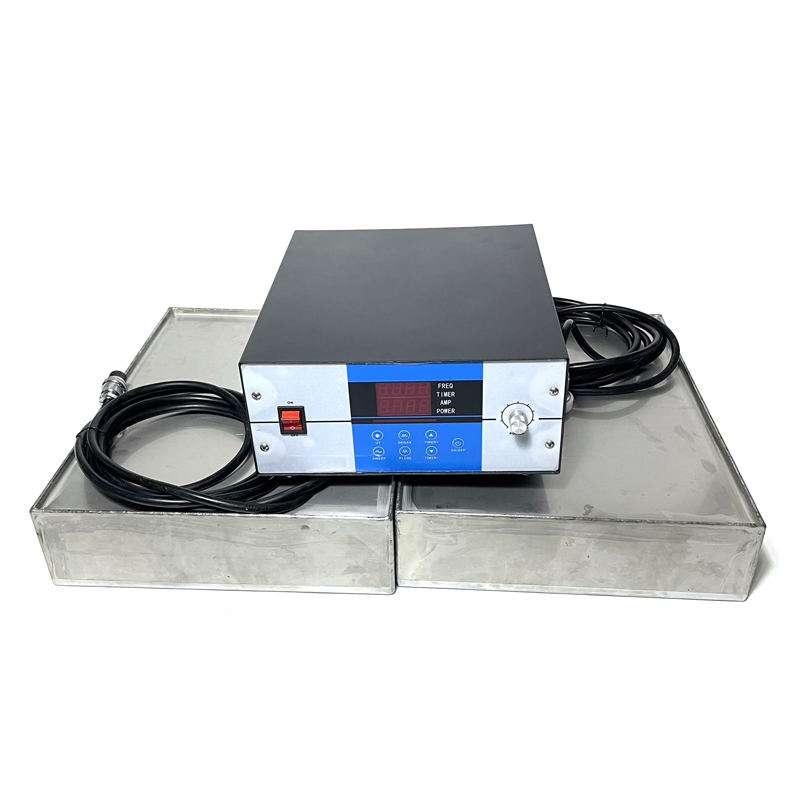

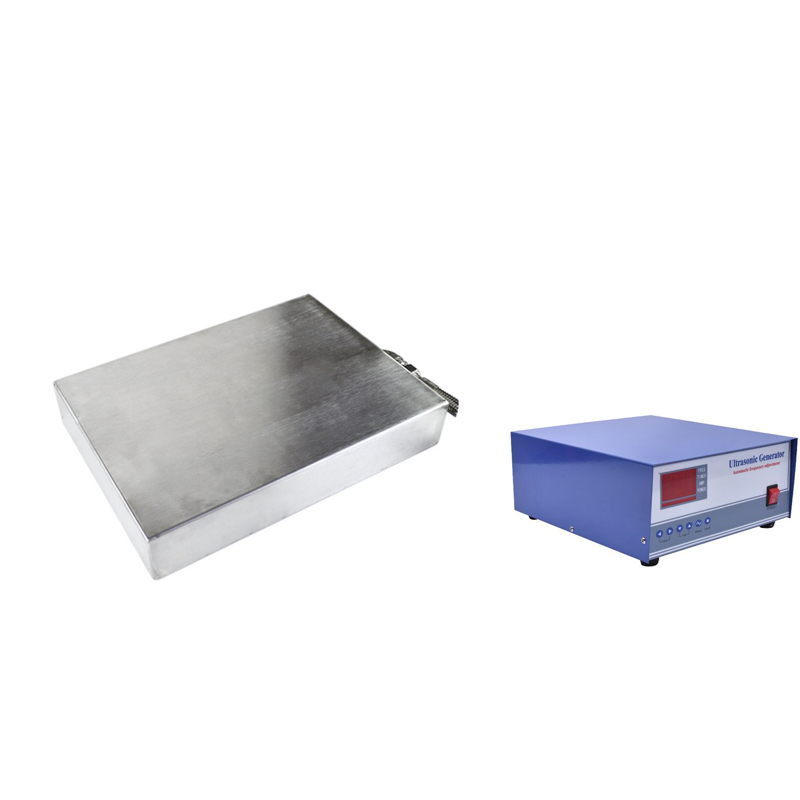

product mix

1: All stainless steel structure, acid and alkali resistant, beautiful and durable.

2: The split structure is adopted, and the high-frequency connection with socket is adopted between the vibrating plate and the ultrasonic generator, which is convenient for use and maintenance.

3: The installation layout is flexible. According to different needs, it can be made into three types: bottom shock type, side shock type and top shock type to meet different cleaning requirements.

4: Advantages of ultrasonic vibration plate, convenient for maintenance

5: When the power of the trough ultrasonic cleaner is too small, the input vibrating plate device can be used. If a vibrating plate device is added to the existing cleaning tank, it will be refitted into an ultrasonic cleaning machine. It is also a low-cost way.

| Type | Diamention(mm) | Frequency (Khz) | Power(W) | Ultrasonic Transducer |

| PU-UITP300W | 300*190*100 | 25,28,33,40,80,130 | 300 | 6 |

| PU-UITP600W | 360*275*100 | 25,28,33,40,80,130 | 600 | 12 |

| PU-UITP1000W | 450*350*100 | 25,28,33,40,80,130 | 1000 | 20 |

| PU-UITP1200W | 470*380*100 | 25,28,33,40,80,130 | 1200 | 24 |

| PU-UITP1500W | 520*450*100 | 25,28,33,40,80,130 | 1500 | 30 |

| PU-UITP1800W | 560*450*100 | 25,28,33,40,80,130 | 1800 | 36 |

| PU-UITP2000W | 650*450*100 | 25,28,33,40,80,130 | 2000 | 40 |

| PU-UITP2400W | 740*520*100 | 25,28,33,40,80,130 | 2400 | 48 |

| PU-UITP3000W | 820*540*100 | 25,28,33,40,80,130 | 3000 | 60 |

| PU-UITP5000W | 1200*590*100 | 25,28,33,40,80,130 | 5000 | 100 |

| OEM Ultrasonic Immersible Transducer Pack(Size, Frequency,Power) |

2000W Submersible Type Ultrasonic Cleaning Transducer And Frequency Generator For Cleaner Parts

标签:Ultrasonic Cleaner, Ultrasonic Cleaning Machine, Ultrasonic Cleaning Transducer, Ultrasonic Generator, ultrasonic vibration plate, Ulttrasonic Cleaning Generator

Send Inquiry

Immersible Ultrasound Transducer Vibrating Plate For Cleaning System 1200W 28KHZ 40KHZ

Immersible Ultrasound Transducer Vibrating Plate For Cleaning System 1200W 28KHZ 40KHZ Industrial Ultrasonic Cleaning Machine Immersible Ultrasonic plate Ultrasonic Transducer Vibration Plate

Industrial Ultrasonic Cleaning Machine Immersible Ultrasonic plate Ultrasonic Transducer Vibration Plate 1000W 20KHZ 40KHZ Immersible Ultrasonic Transducer For Countertop Automated Cleaning System

1000W 20KHZ 40KHZ Immersible Ultrasonic Transducer For Countertop Automated Cleaning System Immersion Ultrasonic Cleaning Submersible Ultrasonic Transducers Plate Submersible Ultrasonic Cleaner

Immersion Ultrasonic Cleaning Submersible Ultrasonic Transducers Plate Submersible Ultrasonic Cleaner Waterproof Ultrasonic Immersible Transducer For Dishes Metal Degreaser Washer Machine

Waterproof Ultrasonic Immersible Transducer For Dishes Metal Degreaser Washer Machine Industrial Ultrasound Cleaning Machine Vibration Generator Immersible Ultrasonic Cleaning Machine

Industrial Ultrasound Cleaning Machine Vibration Generator Immersible Ultrasonic Cleaning Machine Submersible Ultrasonic Transducers Immersible Underwater Ultrasonic Transducer Vibrator Plate

Submersible Ultrasonic Transducers Immersible Underwater Ultrasonic Transducer Vibrator Plate 90L Tank Ultrasound Cleaning Machine Immersible Ultrasonic Cleaner Vibrating Transducer Plate

90L Tank Ultrasound Cleaning Machine Immersible Ultrasonic Cleaner Vibrating Transducer Plate 28KHZ or 40KHZ 3000W Frequency Sweep Ultrasonic Generator For Industrial Submersible Ultrasonic Cleaner

28KHZ or 40KHZ 3000W Frequency Sweep Ultrasonic Generator For Industrial Submersible Ultrasonic Cleaner 28KHZ Underwater Ultrasonic Piezoelectric Transducer For Cleaning Electronic Parts

28KHZ Underwater Ultrasonic Piezoelectric Transducer For Cleaning Electronic Parts Customized 28/40KHZ Ultrasound Cleaning Machine Immersible Ultrasonic Cleaner Vibrating Transducer Plate

Customized 28/40KHZ Ultrasound Cleaning Machine Immersible Ultrasonic Cleaner Vibrating Transducer Plate 40khz Industrial Ultrasonic Cleaning Immersible Transducer Box With Ultrasonic Generator

40khz Industrial Ultrasonic Cleaning Immersible Transducer Box With Ultrasonic Generator