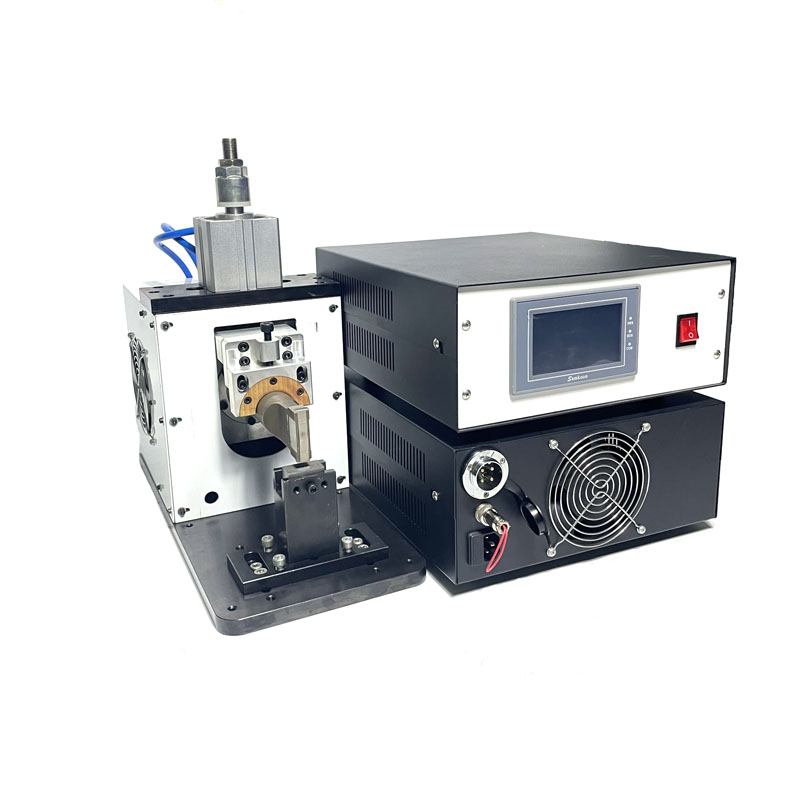

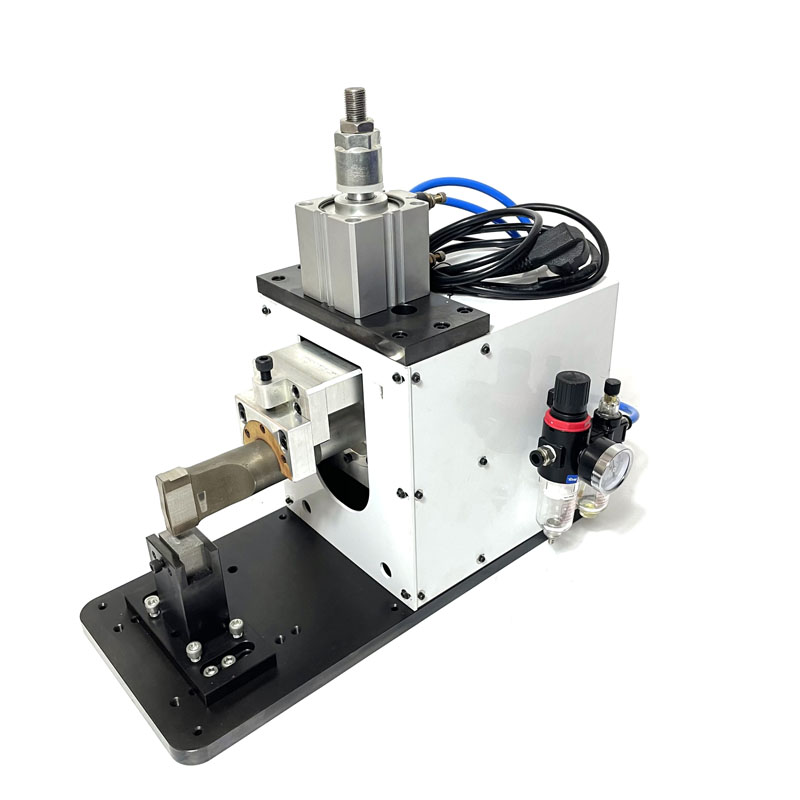

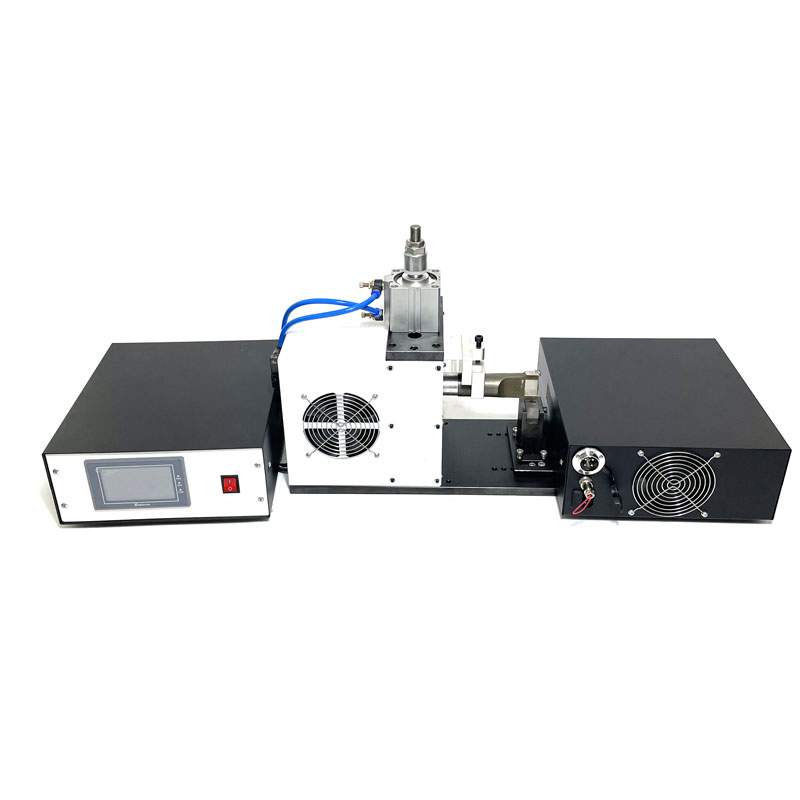

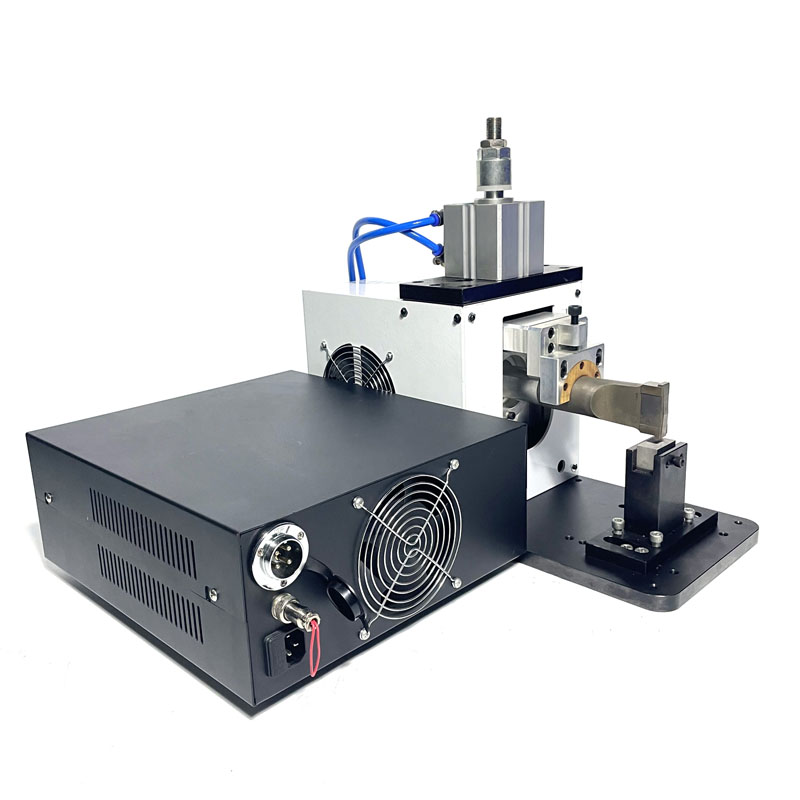

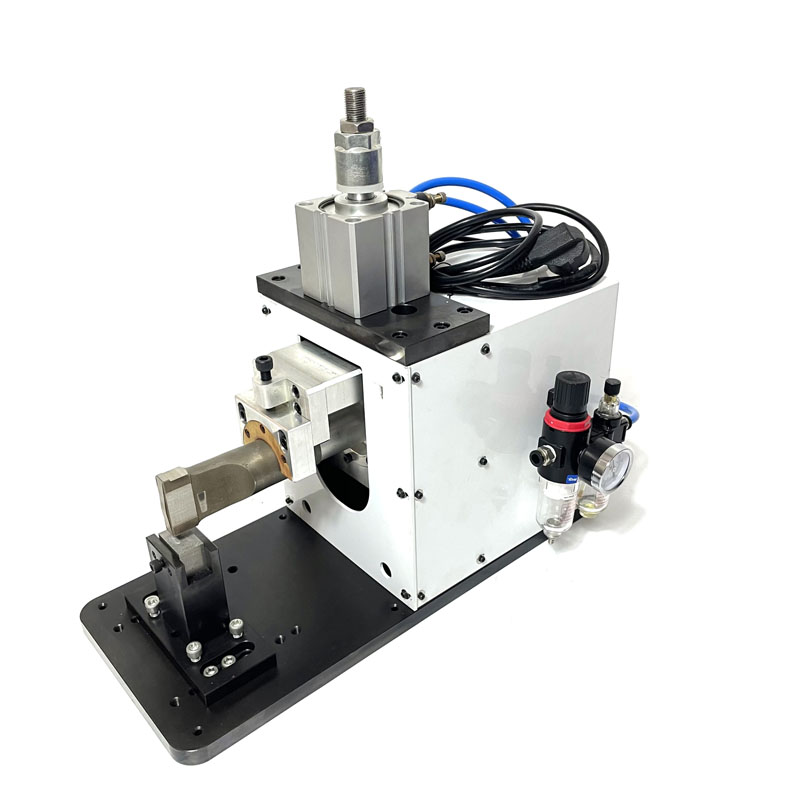

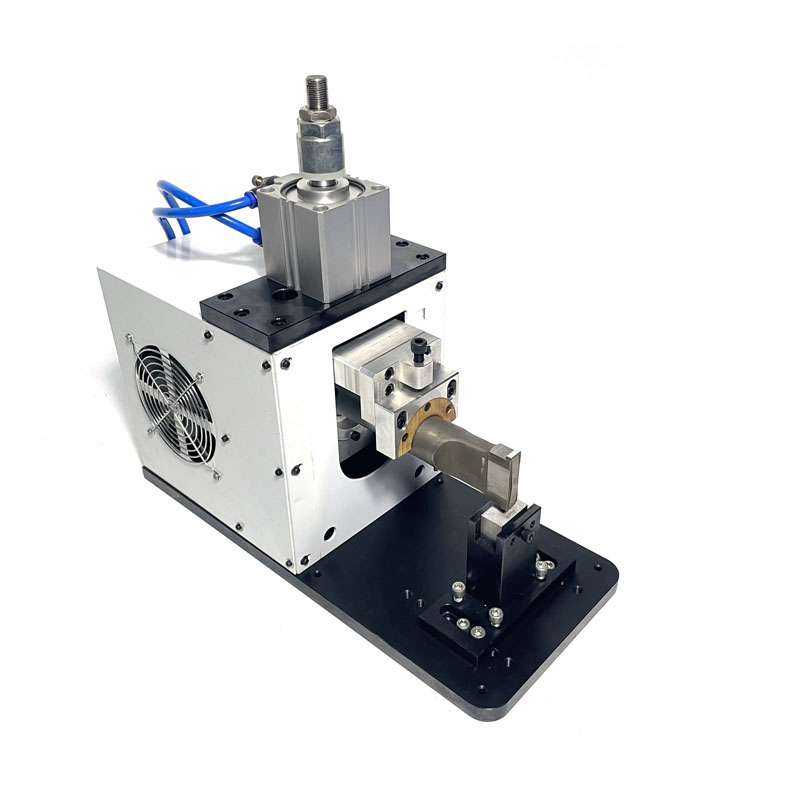

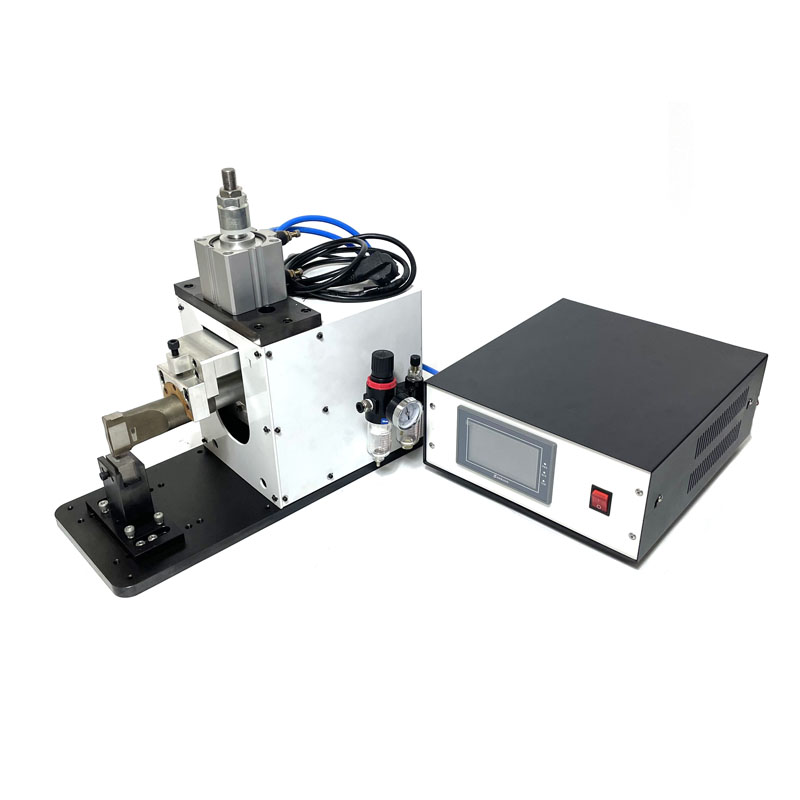

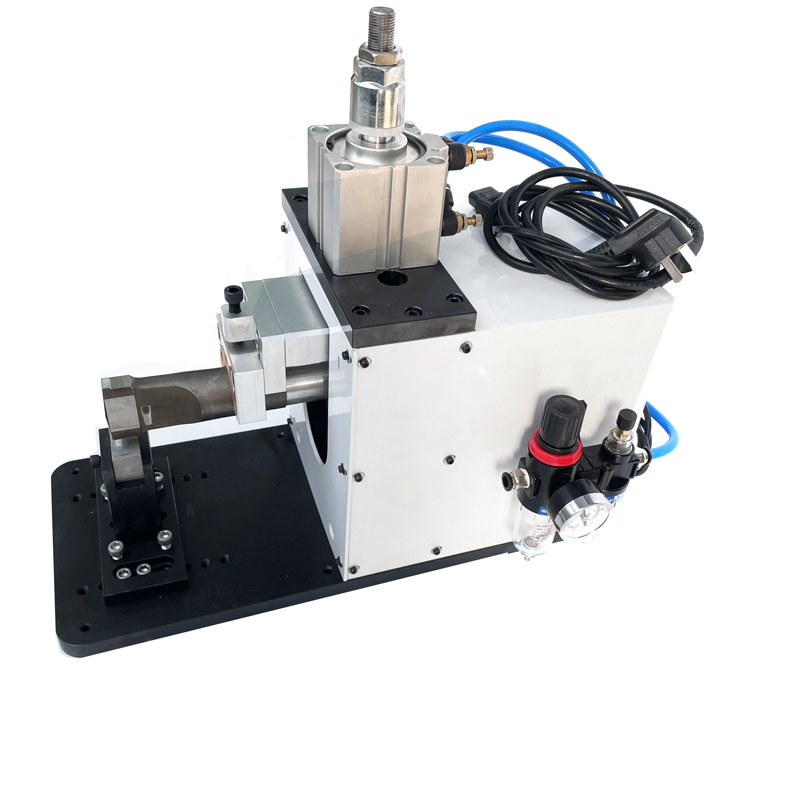

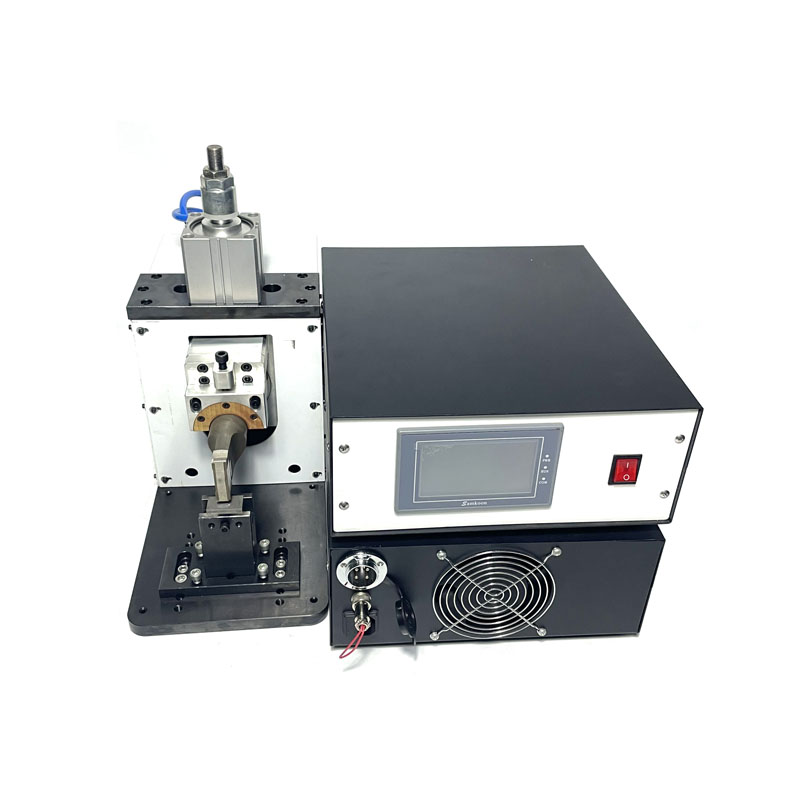

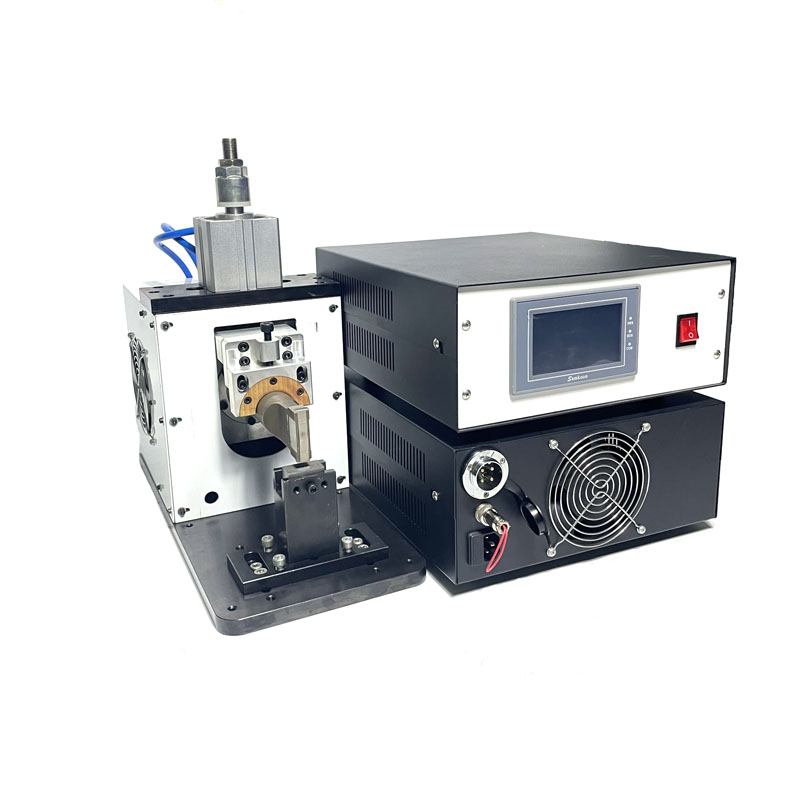

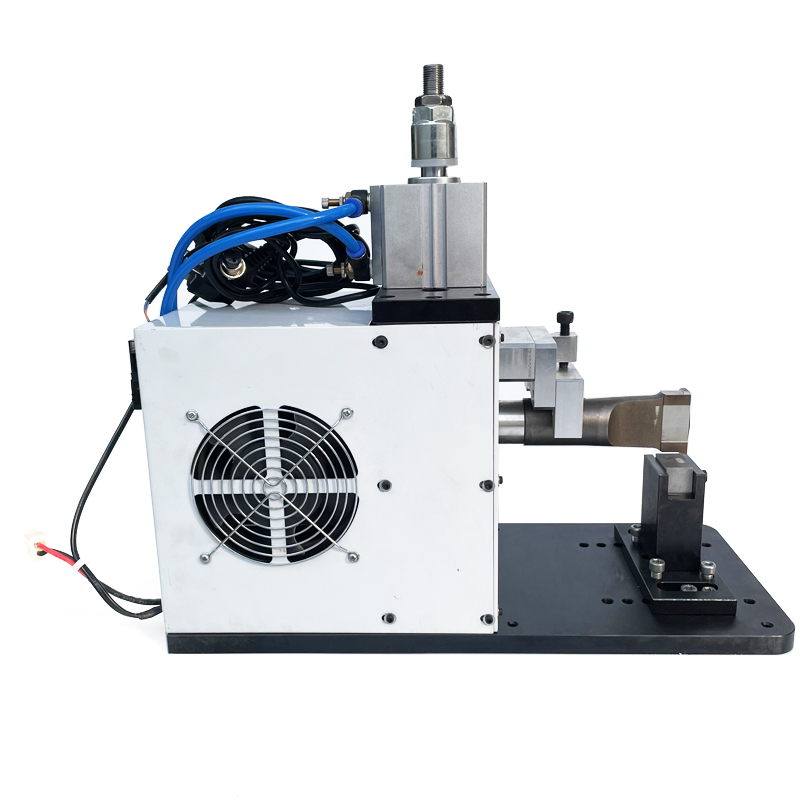

18650 Laboratory Pouch Cell Cylindrical Battery Cap Tab Ultrasonic Welder Machine For Metal Foil Spot Welding Machine

The working principle of metal ultrasonic welding machine: Using high-frequency oscillation signals to convert electrical signals into mechanical vibrations (such as rotation and reciprocating motion), and driving the compression device and transducer through the transmission system to generate ultrasonic vibratio…

The working principle of metal ultrasonic welding machine:

- Using high-frequency oscillation signals to convert electrical signals into mechanical vibrations (such as rotation and reciprocating motion), and driving the compression device and transducer through the transmission system to generate ultrasonic vibration force;

- A closed container composed of a compression device and a transducer;

- Place workpieces or semi-finished products to be processed in the container;

- The high-frequency oscillation signal is generated by the transducer and transmitted to the compression device;

- The working head is driven by a compression device to perform linear reciprocating motion (i.e., a mobile working head);

- A mold surface and fixture (i.e. fixed working head) that matches the workpiece are installed on the working head;

- During work, the workpiece is fixed on a fixed working head through the mold surface or fixture for ultrasonic welding operation;

- After completing a fusion process, release the mold surface and fixture to take out the workpiece to obtain the required product.

The nickel mesh and nickel sheet of a nickel hydrogen battery fuse with each other. Lithium batteries, polymer batteries, copper foil and nickel sheets are fused together, while aluminum foil and aluminum sheet are fused together. Electric wires fuse with each other, forming one or more wires that fuse with each other, and wiring harnesses are welded. Electric wires fuse with various electronic components, contacts, and connectors. The mutual melting of large heat sinks, heat exchange fins, and honeycomb cores for various household appliances and automotive products. High current contacts such as electronic component leads, relays, electromagnetic switches, and non fused switches, as well as mutual melting of dissimilar metal sheets. The sealing, cutting, and sealing of metal pipes can be water tight and airtight.

| Type | Power(W) | Frequency (KHz) |

| PU-MSW2000W | 2000W | 20KHZ |

| PU-MSW2600W | 2600W | 20KHZ |

| PU-MSW3200W | 3200W | 20KHZ |

| PU-MSW4000W | 4000W | 20KHZ |

| PU-MSW800W | 800W | 40khz |

标签:18650 Laboratory Pouch Cell Cylindrical Battery Cap Tab Ultrasonic Welder Machine, Battery Cap Tab Ultrasonic Welder Machine, Ultrasonic Welder Machine For Metal Foil Spot Welding Machine

Send Inquiry

Lab Ultrasonic Battery Spot Welder Welding Machine For Li-ion Battery Cathode Electrode Sheets

Lab Ultrasonic Battery Spot Welder Welding Machine For Li-ion Battery Cathode Electrode Sheets Lab Polymer Battery Ni Al Tab Automatic Ultrasonic Metal Spot Welder Welding Machine

Lab Polymer Battery Ni Al Tab Automatic Ultrasonic Metal Spot Welder Welding Machine Ultrasonic Metal Spot Welding Machine 20KHZ 2000W Metal Welding Machine Copper And Aluminum Welding

Ultrasonic Metal Spot Welding Machine 20KHZ 2000W Metal Welding Machine Copper And Aluminum Welding Full Automatic Aluminum Sheet copper wire Ultrasonic Wire Harness Welding Machine And Power Supply Generator

Full Automatic Aluminum Sheet copper wire Ultrasonic Wire Harness Welding Machine And Power Supply Generator Ultrasonic Terminals Automobile Copper Wiring Welder Metal Machinery Wire Harness Welding Equipment Ultrasonic Welding Machine

Ultrasonic Terminals Automobile Copper Wiring Welder Metal Machinery Wire Harness Welding Equipment Ultrasonic Welding Machine Au Fe Ni Ag Tab Ultrasonic Metal Spot Welder Welding Machine for Pouch Cell Preparation

Au Fe Ni Ag Tab Ultrasonic Metal Spot Welder Welding Machine for Pouch Cell Preparation 20kHz Ultrasonic Metal Spot Welder For Lithium Ion Battery Tabs Lithium Battery Cathode And Sound Generator

20kHz Ultrasonic Metal Spot Welder For Lithium Ion Battery Tabs Lithium Battery Cathode And Sound Generator Ultrasonic Metal Welding Machine For Non Ferrous Metal Welding Aluminium Copper Brass Wires Spot Welding Machine

Ultrasonic Metal Welding Machine For Non Ferrous Metal Welding Aluminium Copper Brass Wires Spot Welding Machine 2000W 20KHZ Ultrasonic Metal Welding Machine for Battery Cell with Aluminum Foils Welded to Copper Mesh

2000W 20KHZ Ultrasonic Metal Welding Machine for Battery Cell with Aluminum Foils Welded to Copper Mesh 18650 Laboratory Pouch Cell Cylindrical Battery Cap Tab Ultrasonic Welder Machine For Metal Foil Spot Welding Machine

18650 Laboratory Pouch Cell Cylindrical Battery Cap Tab Ultrasonic Welder Machine For Metal Foil Spot Welding Machine 4000W Lithium Battery Cap Pneumatic Ultrasonic Metal Spot Welder Welding Machine With Piezo Generator

4000W Lithium Battery Cap Pneumatic Ultrasonic Metal Spot Welder Welding Machine With Piezo Generator Battery Ultrasonic Spot Welder Machine For 18650 & Pouch Cell Al/Ni/Cu Metal Tab Foil Welding

Battery Ultrasonic Spot Welder Machine For 18650 & Pouch Cell Al/Ni/Cu Metal Tab Foil Welding