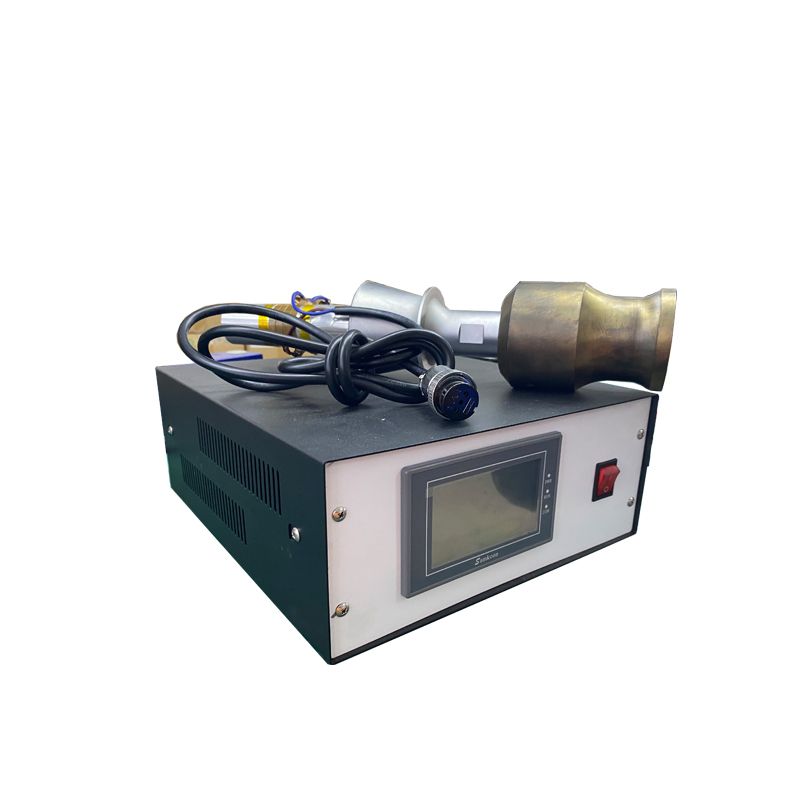

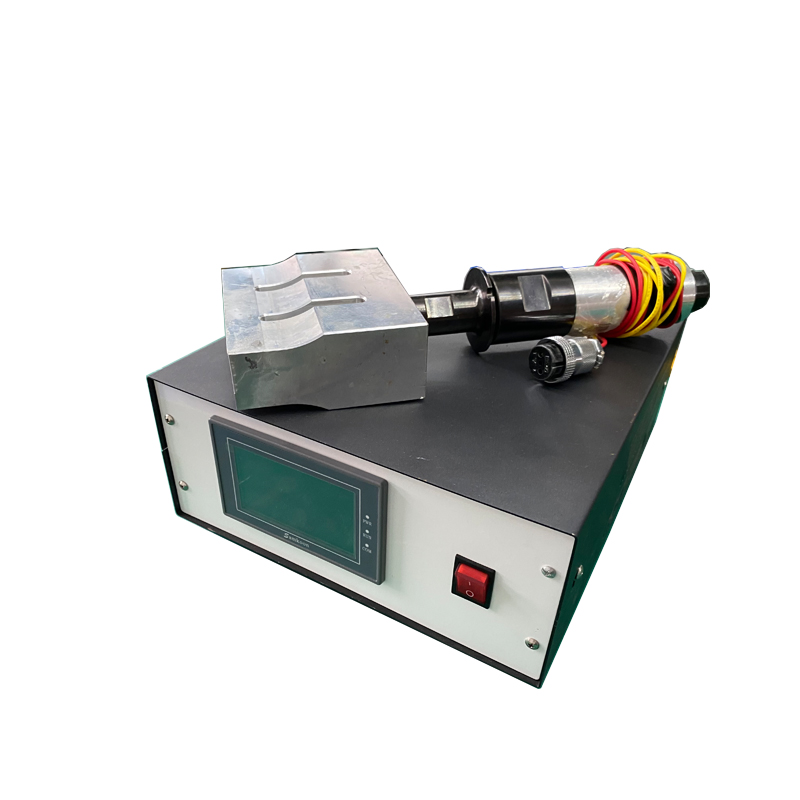

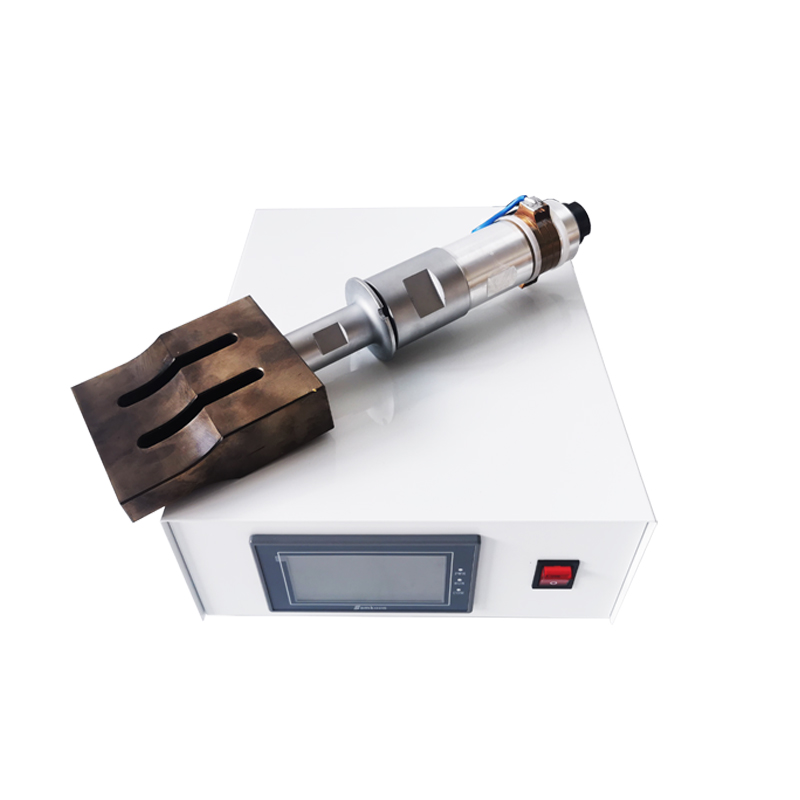

1800W 15KHZ Low Frequency Ultrasonic Plastic Welding Transducer And Generator For Plastic Welder Machine

Features of ultrasonic plastic welding transducer The front pressing block is made of LY12 alloy aluminum, with fast ultrasonic transmission speed, small negative reactance and high conversion efficiency;Self developed and manufactured piezoelectric ceramic chips with stable performance, high Q value, low heat gen…

Features of ultrasonic plastic welding transducer

- The front pressing block is made of LY12 alloy aluminum, with fast ultrasonic transmission speed, small negative reactance and high conversion efficiency;

- Self developed and manufactured piezoelectric ceramic chips with stable performance, high Q value, low heat generation and high electrical conversion efficiency;

- The preloading screw is made of 12.9 high-strength materials to ensure no looseness and fracture under high-frequency oscillation;

- The electrode is made of beryllium bronze plated lead-free solder wire with good conductivity;

- Full inspection to ensure the yield;

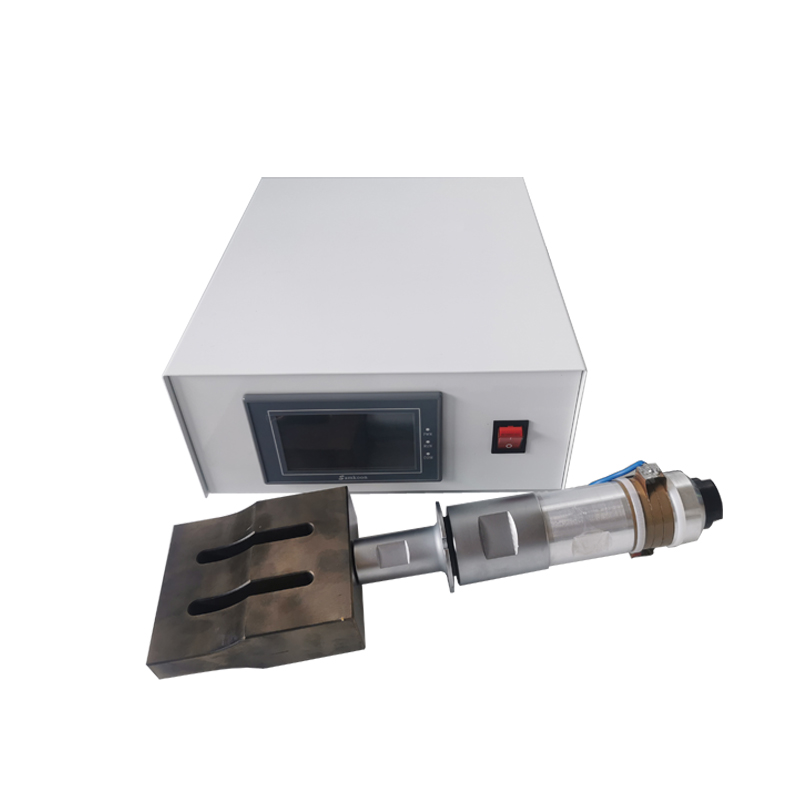

Use of ultrasonic welding transducer:

The ultrasonic power supply transducer transmit ultrasonic energy to the welding area through the upper weldment. Since the welding area, that is, the interface between two welds, has large sound resistance, local high temperature will be generated. Due to the poor thermal conductivity of plastic, nylon, chemical fiber, non-woven fabric, multilayer cloth, gold cloth and other materials, they cannot be distributed in time and are gathered in the welding area, resulting in rapid melting of the two contact surfaces. After a certain pressure is added, they are fused into one. When the ultrasonic wave stops acting, the pressure will continue for some time to solidify and form a solid molecular chain to achieve the purpose of welding.

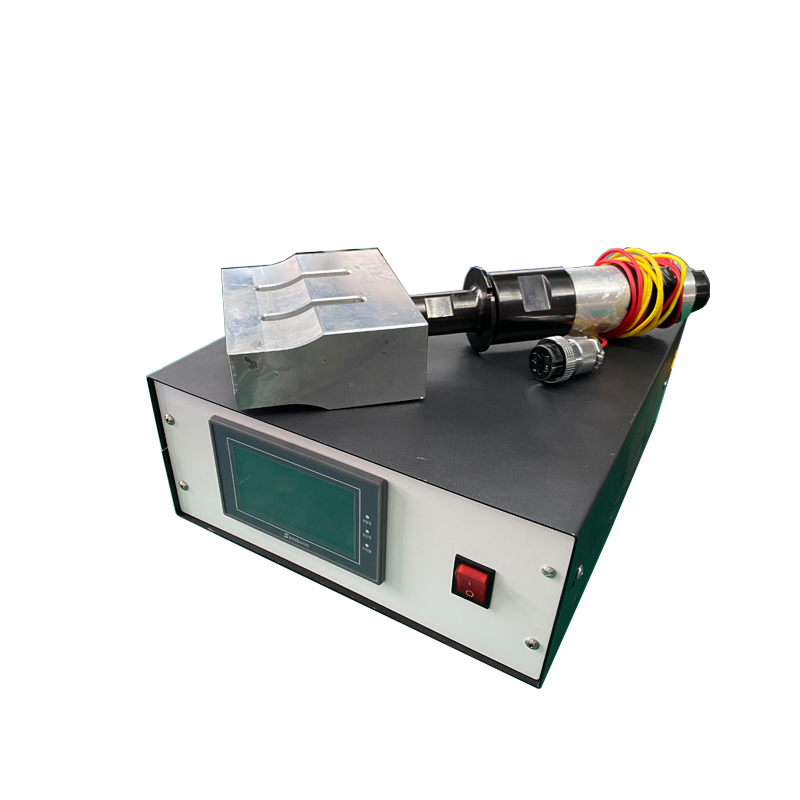

| Type | Full-length(mm) | Joint Bolt(mm) | Frequency(KHz) | Resonance Impedance(Ω) | Capacity(pF) | Input Power (W) |

| PLS-HJHNQ152600 | 153 | M20×1.5 | 15 | 15 | 13000 | 2600 |

| PLS-HJHNQ152000 | 167 | M20×1.5 | 15 | 10 | 9500 | 2000 |

| PLS-HJHNQ202000 | 128 | M18×1 | 20 | 10 | 11000 | 2000 |

| PLS-HJHNQ30500 | 77 | M10×1.5 | 30 | 5 | 5500 | 500 |

| PLS-HJHNQ28200 | 92.1 | M10×1 | 28 | 20 | 3000 | 200 |

| PLS-HJHNQ28100 | 91 | M8×1 | 28 | 25 | 2200 | 100 |

| PLS-HJHNQ28250 | 94 | 1/2-20 UNF | 28 | 20 | 4000 | 250 |

| PLS-HJHNQ202000 | 128 | 1/2-20 UNF | 20 | 10 | 20000 | 2000 |

| PLS-HJHNQ201500 | 124 | 1/2-20 UNF | 20 | 10 | 16000 | 1500 |

| PLS-HJHNQ38100 | 66 | M8×1.25 | 38 | 40 | 1200 | 100 |

| PLS-HJHNQ38200 | 65 | M8×1 | 38 | 14 | 3300 | 200 |

标签:Low Frequency Ultrasonic Plastic Welding Transducer, ultrasonic plastic welding transducer, Ultrasonic Plastic Welding Transducer And Generator, ultrasonic power supply transducer, ultrasonic welding transducer

Send Inquiry

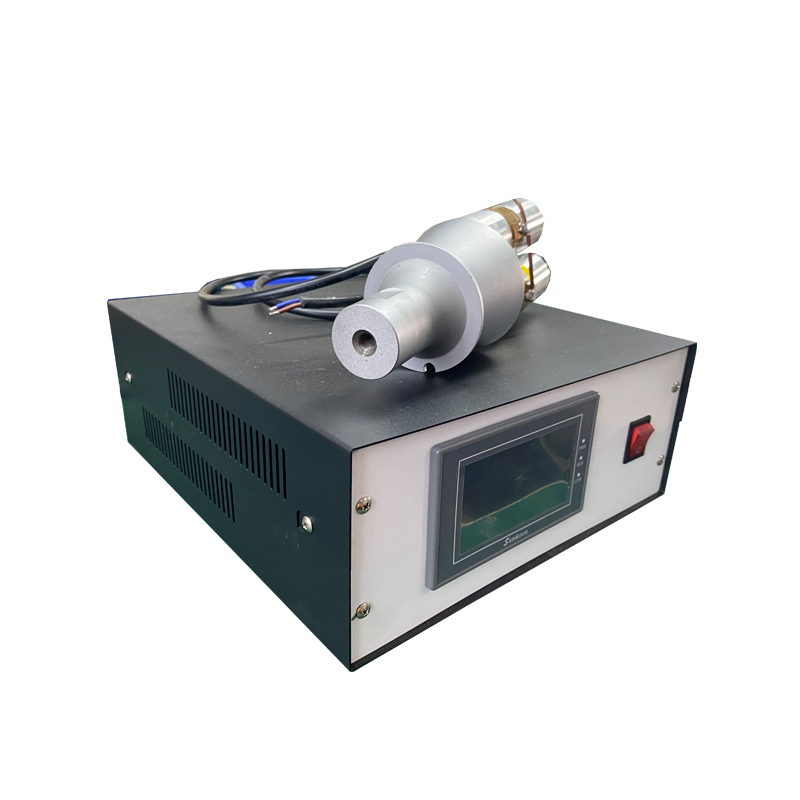

1800W 20KHZ Low Power Ultrasonic Plastic Welding Transducer And Generator For Metal Welding System

1800W 20KHZ Low Power Ultrasonic Plastic Welding Transducer And Generator For Metal Welding System 20KHZ 2000W Ultrasonic Plastic Welding Generator Transducer Horn For Nonwoven Face Mask Welding Machine

20KHZ 2000W Ultrasonic Plastic Welding Generator Transducer Horn For Nonwoven Face Mask Welding Machine Ultrasonic Welding Transducer Booster Welding Horn 15khz 18khz 20khz Ultrasonic Generator

Ultrasonic Welding Transducer Booster Welding Horn 15khz 18khz 20khz Ultrasonic Generator 2000W 15KHZ Ultrasonic Vibrating Plastic Welding Transducer And Generator For Plastic Welder Equipment

2000W 15KHZ Ultrasonic Vibrating Plastic Welding Transducer And Generator For Plastic Welder Equipment 3000W 20KHZ Ultrasonic Plastic Wleding Transducer Generator With Booster Horn For Ultrasonic Welding Machine

3000W 20KHZ Ultrasonic Plastic Wleding Transducer Generator With Booster Horn For Ultrasonic Welding Machine Industry Ultrasonic Generator Transducer And Booster Horn For Automatic Digital Ultrasonic Welding Machine

Industry Ultrasonic Generator Transducer And Booster Horn For Automatic Digital Ultrasonic Welding Machine 15khz 1800W Ultrasonic Welding Transducer Genertor With Booster And Flange And Steel Horn for Welding Machine

15khz 1800W Ultrasonic Welding Transducer Genertor With Booster And Flange And Steel Horn for Welding Machine 1800W 15KHZ Low Frequency Ultrasonic Plastic Welding Transducer And Generator For Plastic Welder Machine

1800W 15KHZ Low Frequency Ultrasonic Plastic Welding Transducer And Generator For Plastic Welder Machine 1500W Ultrasonic Welding Transducer Horn Plastic Ultrasonic Welding Generator Parts Aluminium Mold

1500W Ultrasonic Welding Transducer Horn Plastic Ultrasonic Welding Generator Parts Aluminium Mold 20KHz 15KHz Ultrasonic Plastic Welding Generator With Transducer & Horn For Non-woven Welding Machine

20KHz 15KHz Ultrasonic Plastic Welding Generator With Transducer & Horn For Non-woven Welding Machine 20KHZ Ultrasonic Welding Machine Transducer Generator Booster Horn For Metal Ultrasonic Welding Machine

20KHZ Ultrasonic Welding Machine Transducer Generator Booster Horn For Metal Ultrasonic Welding Machine 1000W 20KHZ Piezoelectric Ultrasonic Plastic Welding Transducer And Generator For Metal Welding Machine

1000W 20KHZ Piezoelectric Ultrasonic Plastic Welding Transducer And Generator For Metal Welding Machine