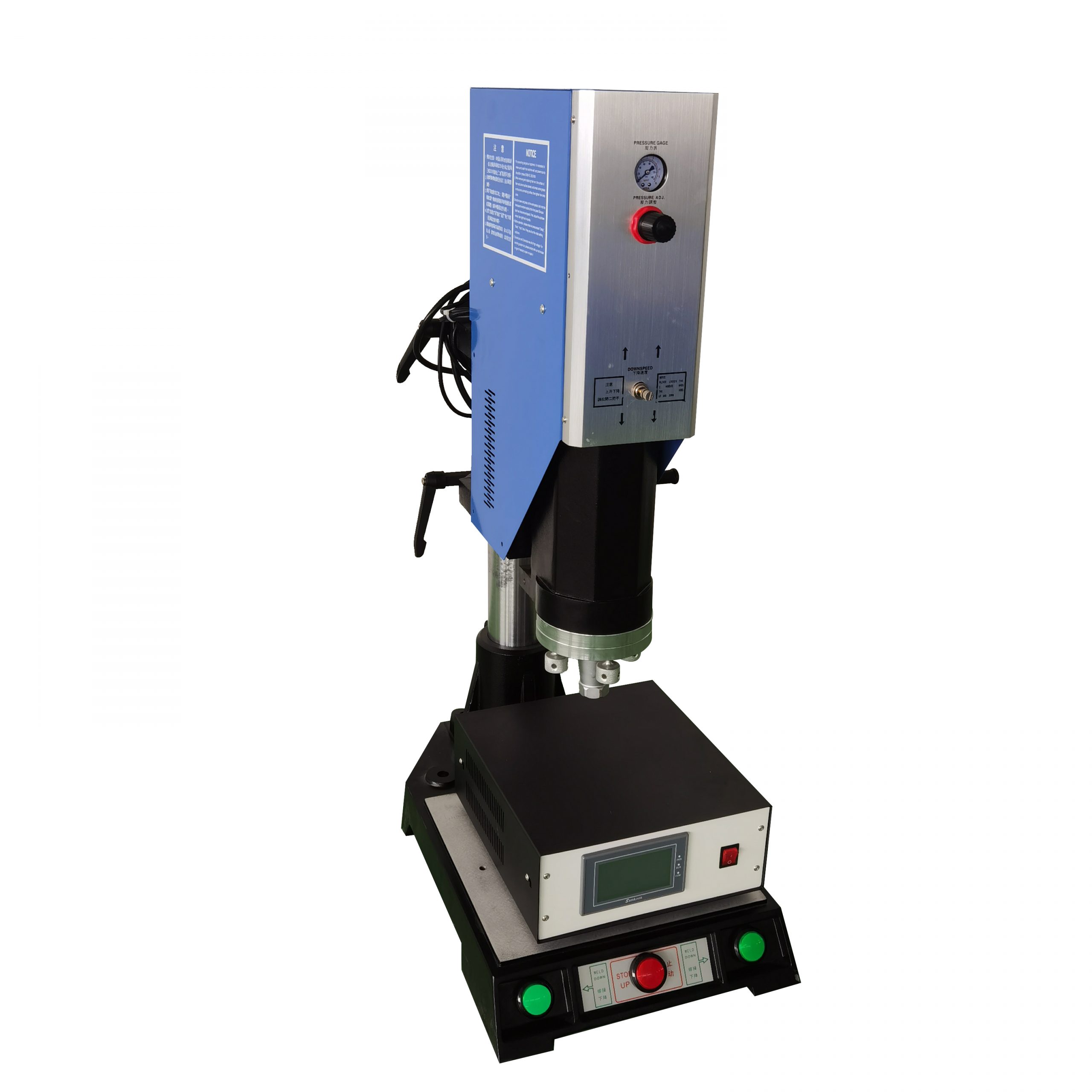

15KHZ 2600W Automatic Frequency Tracking Ultrasonic Welding Machine For ABS PP Plastic Welding PSA Slabs Case

Ultrasonic plastic welding machine is a device that uses ultrasonic technology to fuse thermoplastic plastics into a whole and obtain the required products. This device can be widely used in the automotive industry, packaging industry, toy industry, electronic and electrical industry, etc. Principle of ultrason…

Ultrasonic plastic welding machine is a device that uses ultrasonic technology to fuse thermoplastic plastics into a whole and obtain the required products.

This device can be widely used in the automotive industry, packaging industry, toy industry, electronic and electrical industry, etc.

Principle of ultrasonic plastic welding machine:

- Firstly, the ultrasonic energy is transmitted to the plastic surface to be welded through the upper mold (or concave mold). Due to the friction between the surface and internal molecules, high temperatures are generated, causing the contact surface of the two plastics to quickly melt and then fill in the overlapping position. When the vibration stops, the two materials are tightly connected together, achieving the purpose of welding, while generating huge heat to firmly fix the two products.

- When pressure is applied and continued to be applied, a certain amount of internal stress continues to be generated when the surface is pressed tightly. When the yield point of the material is reached, the chemical bonds break, thus achieving the purpose of welding.

- By utilizing the characteristics of ultrasonic waves that instantly vibrate onto plastic products, it creates a warm feeling similar to being massaged by hand, and has a certain tensile force until the product dissolves. After processing, it can achieve water tightness and air tightness, and food placed in the mouth will not melt. Generally, it can be formed in one go to meet the user’s needs.

- Using high-frequency waves to transmit to the metal body, countless small bubbles smaller than pinholes are generated inside the metal body, and then a large current is applied to force them to grow rapidly and collide with each other, achieving the goal of welding. Author: Kaige from Qingda Ultrasound Technology

| Type | Power(W) | Frequency (KHz) |

| PU-UWM600W | 600W | 15KHZ/20KHZ/28KHZ/40KHZ |

| PU-UWM900W | 900W | 15KHZ/20KHZ/28KHZ/40KHZ |

| PU-UWM1000W | 1000W | 15KHZ/20KHZ/28KHZ/30KHZ |

| PU-UWM1500W | 1500W | 15KHZ/20KHZ |

| PU-UWM1800W | 1800W | 15KHZ/20KHZ |

| PU-UWM2000W | 2000W | 15KHZ/20KHZ |

| PU-UWM2600W | 2600W | 15KHZ |

| PU-UWM3200W | 3200W | 15KHZ |

| PU-UWM4200W | 4200W | 15KHZ |

标签:Automatic Frequency Tracking Ultrasonic Welding Machine For ABS PP Plastic

Send Inquiry

You May Also Like

15kHz/20kHz/28kHz/35kHz Ultrasonic Weld Machine Ultrasonic Plastic Welding Machine With Piezo Generator

15kHz/20kHz/28kHz/35kHz Ultrasonic Weld Machine Ultrasonic Plastic Welding Machine With Piezo Generator Customized Ultrasonic Welding Machine PSA Breathe Valve Ultrasonic Welding Machine 15kHz 2600W

Customized Ultrasonic Welding Machine PSA Breathe Valve Ultrasonic Welding Machine 15kHz 2600W 20khz Ultrasonic Plastic Welding Machine For Toys Plastic Body Parts/Car Plastic Element Welding Machine

20khz Ultrasonic Plastic Welding Machine For Toys Plastic Body Parts/Car Plastic Element Welding Machine Automatic Ultrasonic Ultrasonic Rubber Fabric Nonwoven Welding Transducer Machine With Wave Generator

Automatic Ultrasonic Ultrasonic Rubber Fabric Nonwoven Welding Transducer Machine With Wave Generator PSA Plastic Grading Card Slab Ultrasonic Sealing Machine Welder For Plastic Comics Book Waterproof Case

PSA Plastic Grading Card Slab Ultrasonic Sealing Machine Welder For Plastic Comics Book Waterproof Case Automatic Production Ultrasonic Welding Machine 4200w 2600w 1200w High Power Ultrasonic Plastic Welding Equipment

Automatic Production Ultrasonic Welding Machine 4200w 2600w 1200w High Power Ultrasonic Plastic Welding Equipment Turntable Ultrasonic Plastic Welding Machine And High Frequency Ultrasonic Welding Power Supply Generator

Turntable Ultrasonic Plastic Welding Machine And High Frequency Ultrasonic Welding Power Supply Generator 15K 20K Ultrasonic Welding Cutting Sealing PVC ABS Fabric Customized Welder Ultrasonic Plastic Welding Machine

15K 20K Ultrasonic Welding Cutting Sealing PVC ABS Fabric Customized Welder Ultrasonic Plastic Welding Machine 15khz 20khz 3000w 4200w Plastic Parts Welder Digital Ultrasonic Plastic Welding Machine for PVC PTFE ABS PE PP

15khz 20khz 3000w 4200w Plastic Parts Welder Digital Ultrasonic Plastic Welding Machine for PVC PTFE ABS PE PP 20k 2000w Ultrasonic Welder Pokemon Grading Card Psa Slab Ultrasonic Plastic Welding Machine

20k 2000w Ultrasonic Welder Pokemon Grading Card Psa Slab Ultrasonic Plastic Welding Machine 2600W Welding Machine Ultrasonic Plastic Acrylic Welding Machine For Grading Card Slabs With Transducer Generator

2600W Welding Machine Ultrasonic Plastic Acrylic Welding Machine For Grading Card Slabs With Transducer Generator 20KHZ 2600W Intelligent Ultrasonic Plastic Welding Machine PVC Ultrasonic Plastic Welder With Signal Generator

20KHZ 2600W Intelligent Ultrasonic Plastic Welding Machine PVC Ultrasonic Plastic Welder With Signal Generator