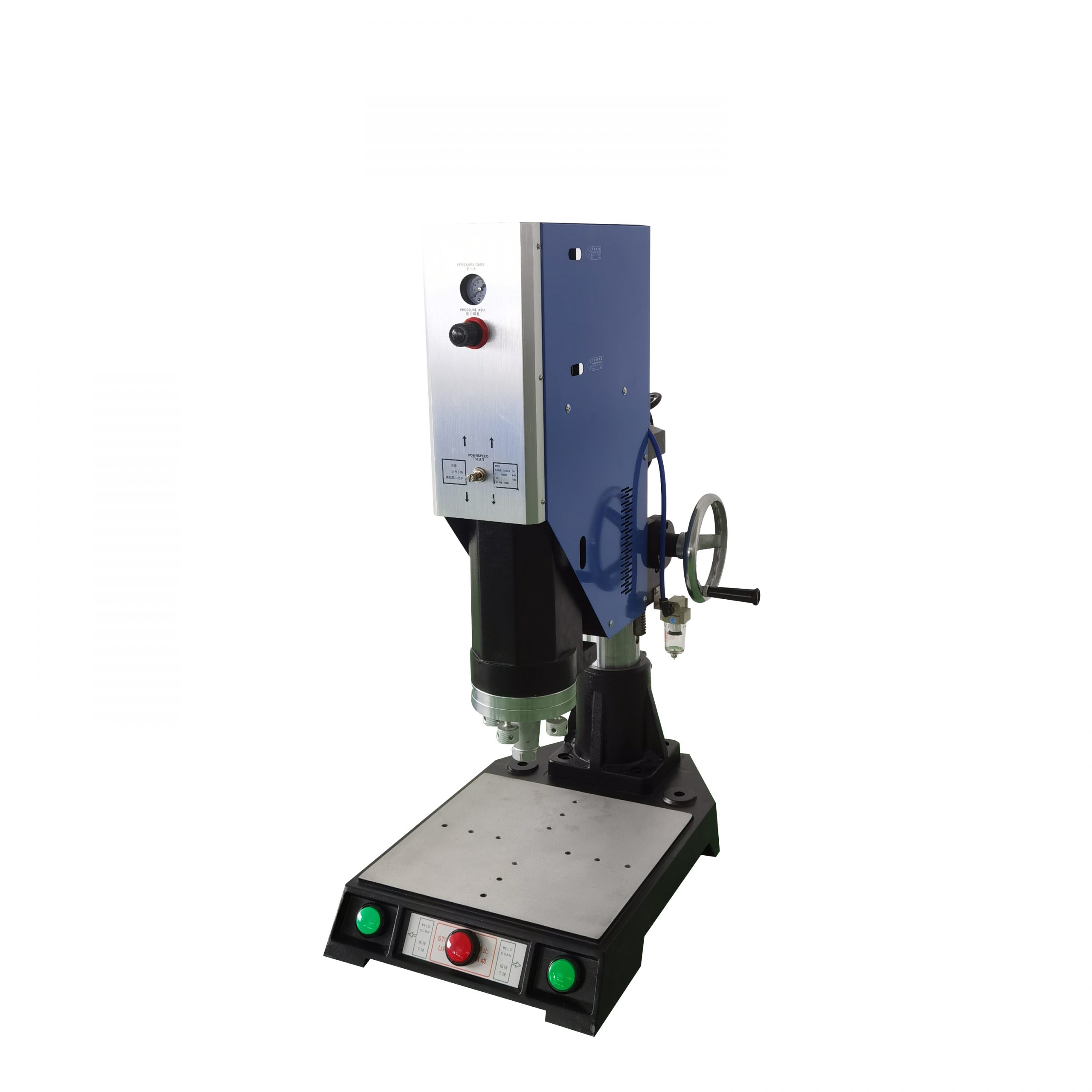

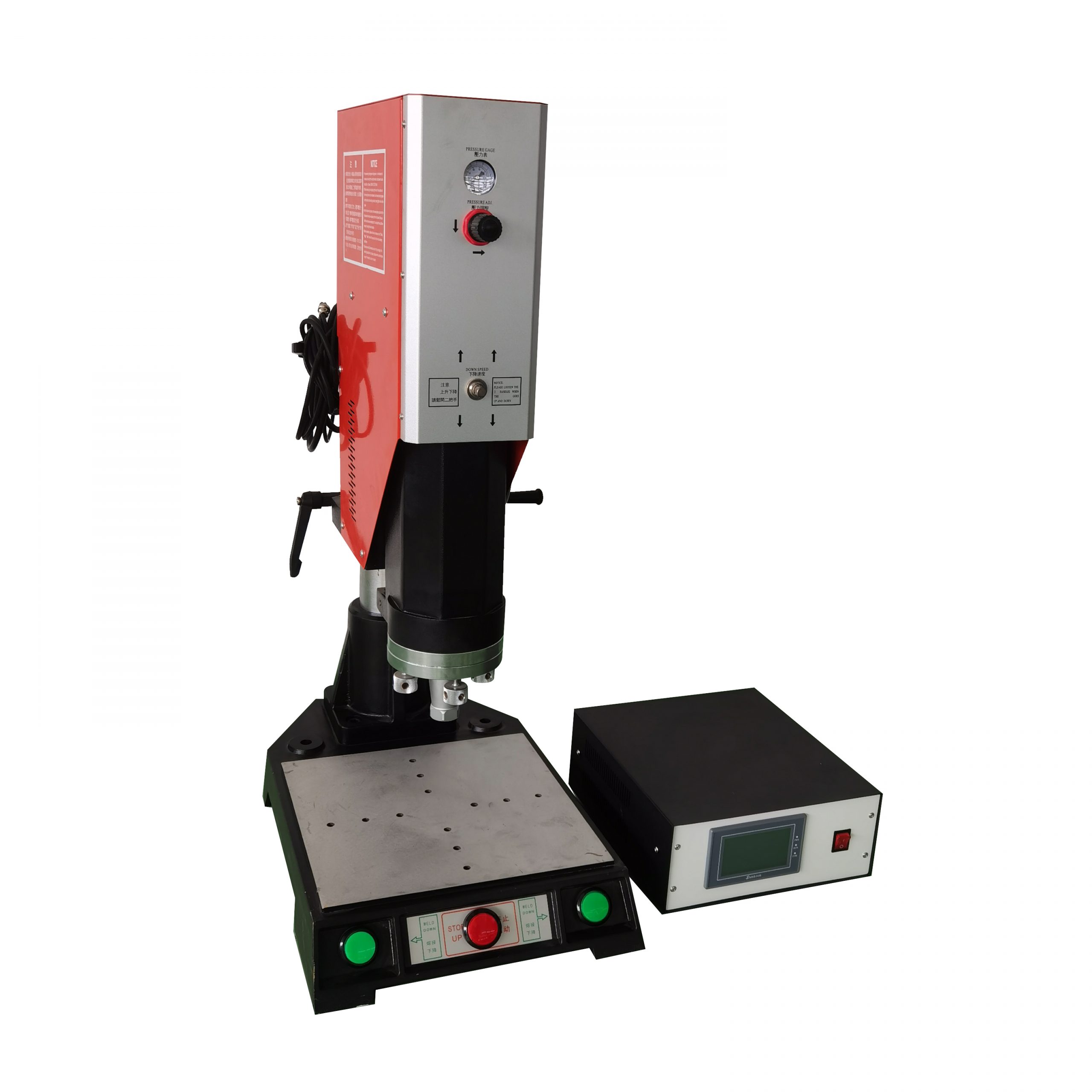

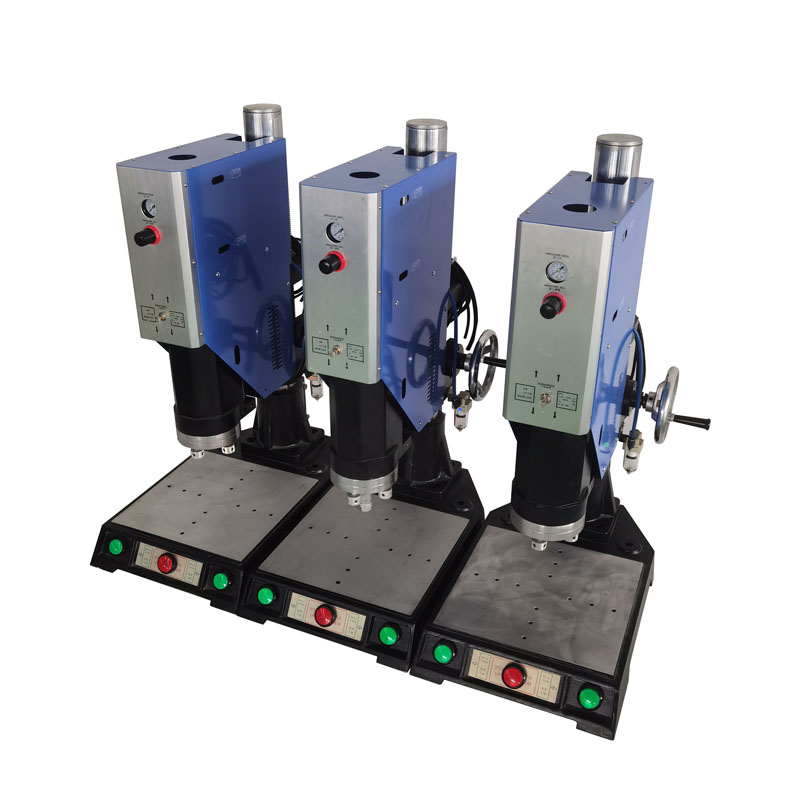

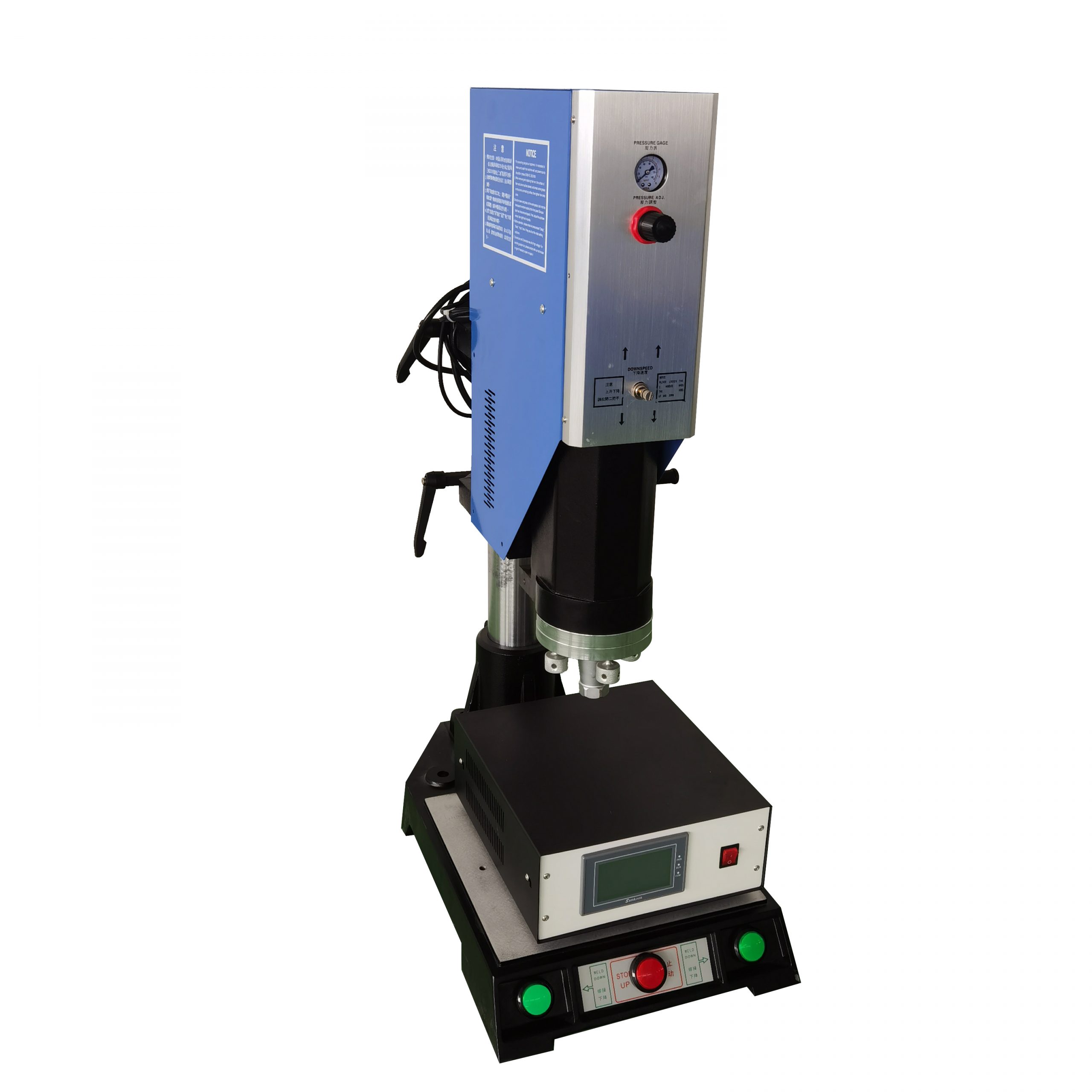

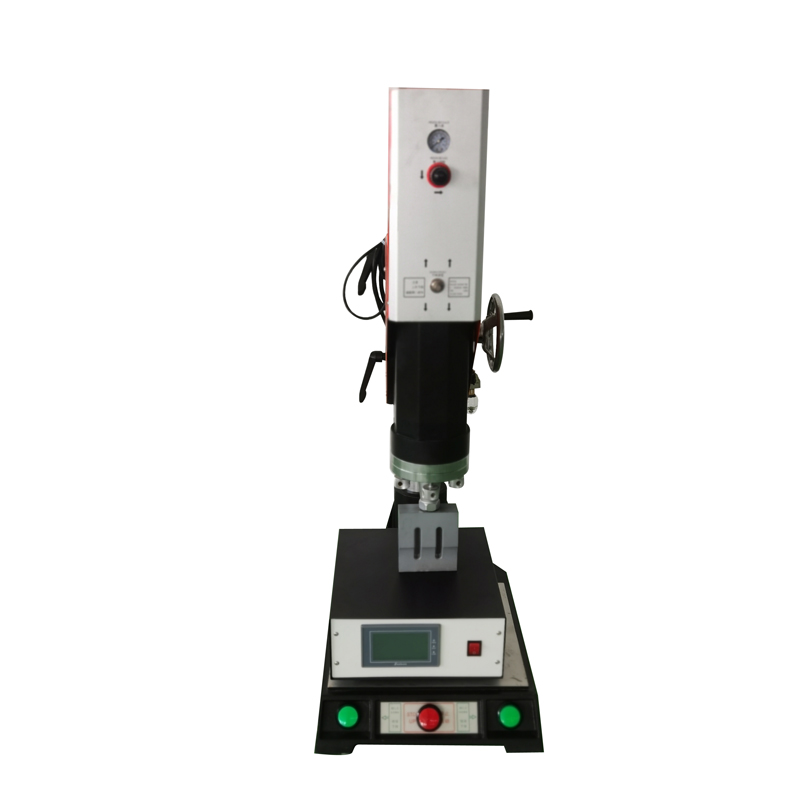

15K 2600W Automatic Frequency Tracking Ultrasonic Welding Machine for ABS PP Plastic Welding PSA Slabs Case

The standard generator module and transducer configuration can achieve two output powers: 1100W, 2200W, and 3300W, respectively. The equipment adopts digital operation control, and welding parameters can be set repeatedly. 2000IW+can also use deep or relative depth mode for welding. The main feature is that the close…

The standard generator module and transducer configuration can achieve two output powers: 1100W, 2200W, and 3300W, respectively. The equipment adopts digital operation control, and welding parameters can be set repeatedly. 2000IW+can also use deep or relative depth mode for welding. The main feature is that the closed loop amplitude control function of power supply voltage/load adjustment can correct the amplitude output changes caused by power supply voltage fluctuations or changes in load conditions. When the power supply voltage fluctuates within the range of ± 10 (excluding load changes), the amplitude drift range caused by this is only ± 2.

Working principle of ultrasonic plastic welding machine

A sound wave with a frequency of 20KHz (Hz). The branch of acoustics that studies the generation, propagation, reception, and various ultrasonic effects and applications of ultrasound is called ultrasonics. The devices that generate ultrasonic waves include mechanical ultrasonic generators (such as gas whistles, sirens, and liquid whistles), electric ultrasonic generators made using the principles of electromagnetic induction and action, and electro-acoustic transducers made using the electrostrictive effect of piezoelectric crystals and the magnetostrictive effect of ferromagnetic materials.

Common faults and solutions of ultrasonic plastic welding machines

Reason for excessive welding: Excessive energy input to the workpiece; The ultrasonic machine has too much power.

| Type | Power(W) | Frequency (KHz) |

| PU-UWM600W | 600W | 15KHZ/20KHZ/28KHZ/40KHZ |

| PU-UWM900W | 900W | 15KHZ/20KHZ/28KHZ/40KHZ |

| PU-UWM1000W | 1000W | 15KHZ/20KHZ/28KHZ/30KHZ |

| PU-UWM1500W | 1500W | 15KHZ/20KHZ |

| PU-UWM1800W | 1800W | 15KHZ/20KHZ |

| PU-UWM2000W | 2000W | 15KHZ/20KHZ |

| PU-UWM2600W | 2600W | 15KHZ |

| PU-UWM3200W | 3200W | 15KHZ |

| PU-UWM4200W | 4200W | 15KHZ |

标签:15K 2600W Automatic Frequency Tracking Ultrasonic Welding Machine, Automatic Frequency Tracking Ultrasonic Welding Machine, Ultrasonic Welding Machine for ABS PP Plastic Welding PSA Slabs Case

Send Inquiry

ABS PP Ultrasonic High Frequency Plastic Welder Plastic Welding Machine For PSA Grading Card Plastic Slabs Case Sealing

ABS PP Ultrasonic High Frequency Plastic Welder Plastic Welding Machine For PSA Grading Card Plastic Slabs Case Sealing Ultrasonic Plastic Welding Machine 15kHz 2600W/20kHz 2000W PSA Grading Card Welding

Ultrasonic Plastic Welding Machine 15kHz 2600W/20kHz 2000W PSA Grading Card Welding 15khz 20khz 3000w 4200w Plastic Parts Welder Digital Ultrasonic Plastic Welding Machine for PVC PTFE ABS PE PP

15khz 20khz 3000w 4200w Plastic Parts Welder Digital Ultrasonic Plastic Welding Machine for PVC PTFE ABS PE PP 20k 2000w Ultrasonic Welder Pokemon Grading Card Psa Slab Ultrasonic Plastic Welding Machine

20k 2000w Ultrasonic Welder Pokemon Grading Card Psa Slab Ultrasonic Plastic Welding Machine 15K 2600W PSA Rigid Plastic Sealing Ultrasonic Grading Playing Card Slab Cases Welding Machine

15K 2600W PSA Rigid Plastic Sealing Ultrasonic Grading Playing Card Slab Cases Welding Machine 20k Ultrasound Polymer Cutting And Welding Machine With Generator

20k Ultrasound Polymer Cutting And Welding Machine With Generator Auto Digital Tracking 15Khz 20Khz Ultrasonic Welding Machine For Welding Small Car Light Automobile Application

Auto Digital Tracking 15Khz 20Khz Ultrasonic Welding Machine For Welding Small Car Light Automobile Application 15KHZ 2600W Automatic Frequency Tracking Ultrasonic Welding Machine For ABS PP Plastic Welding PSA Slabs Case

15KHZ 2600W Automatic Frequency Tracking Ultrasonic Welding Machine For ABS PP Plastic Welding PSA Slabs Case Ultrasonic Plastic Welding Machine Auto Parts Welding Non-woven Cutting And Welding Machine

Ultrasonic Plastic Welding Machine Auto Parts Welding Non-woven Cutting And Welding Machine Customized Ultrasonic Welding Machine PSA Breathe Valve Ultrasonic Welding Machine 15kHz 2600W

Customized Ultrasonic Welding Machine PSA Breathe Valve Ultrasonic Welding Machine 15kHz 2600W Ultrasonic Welding Machine Equipment Automatic Plastic Welding Acrylic Material Ultrasonic Plastic Bonding Machine

Ultrasonic Welding Machine Equipment Automatic Plastic Welding Acrylic Material Ultrasonic Plastic Bonding Machine 3200W 15KHZ Ultrasonic Welding Machine For Sponge Scourer Pad And Generator Control Box

3200W 15KHZ Ultrasonic Welding Machine For Sponge Scourer Pad And Generator Control Box