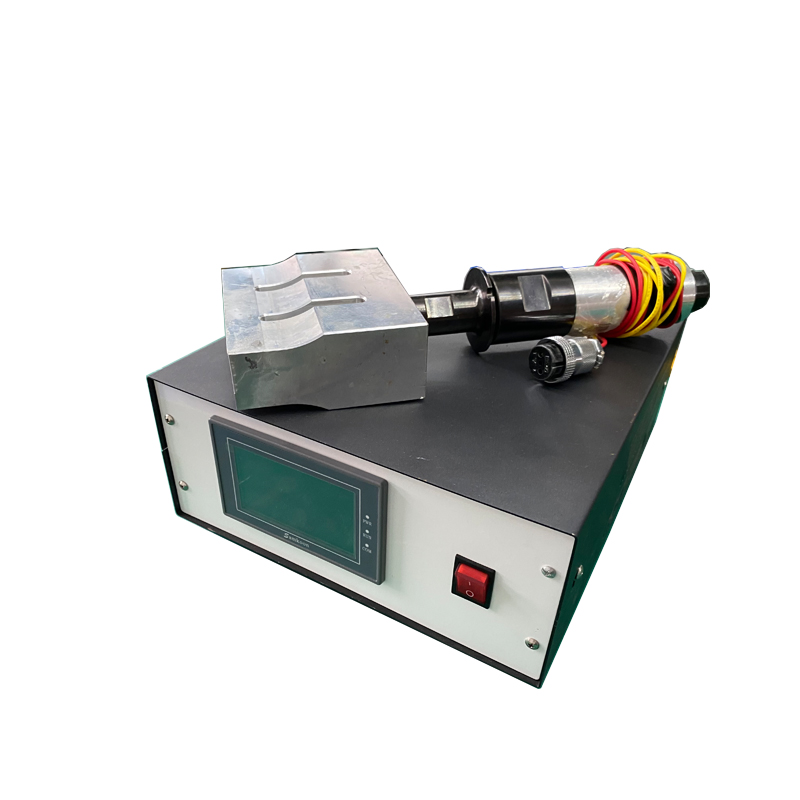

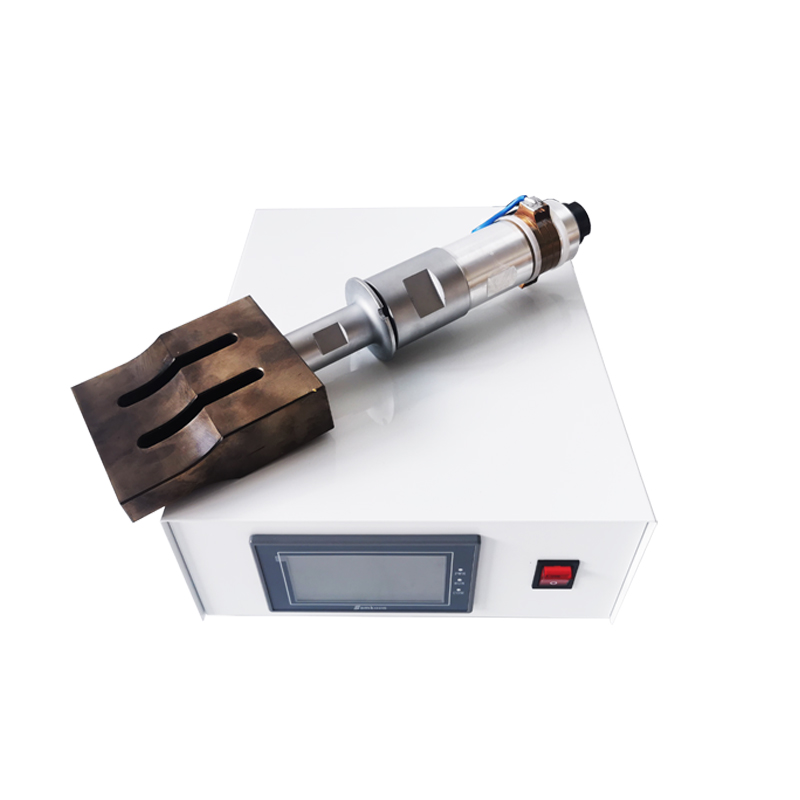

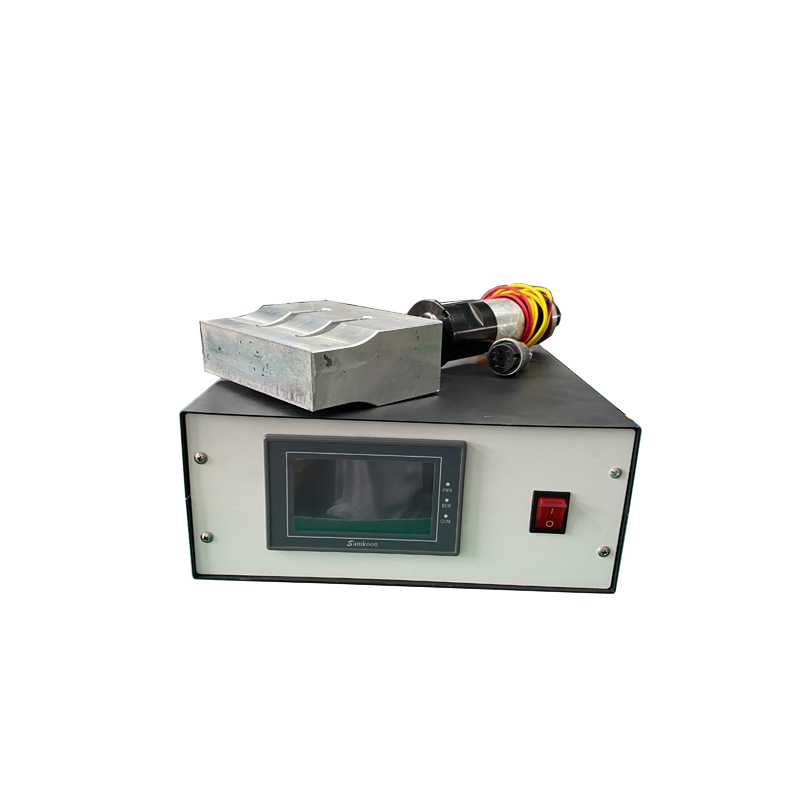

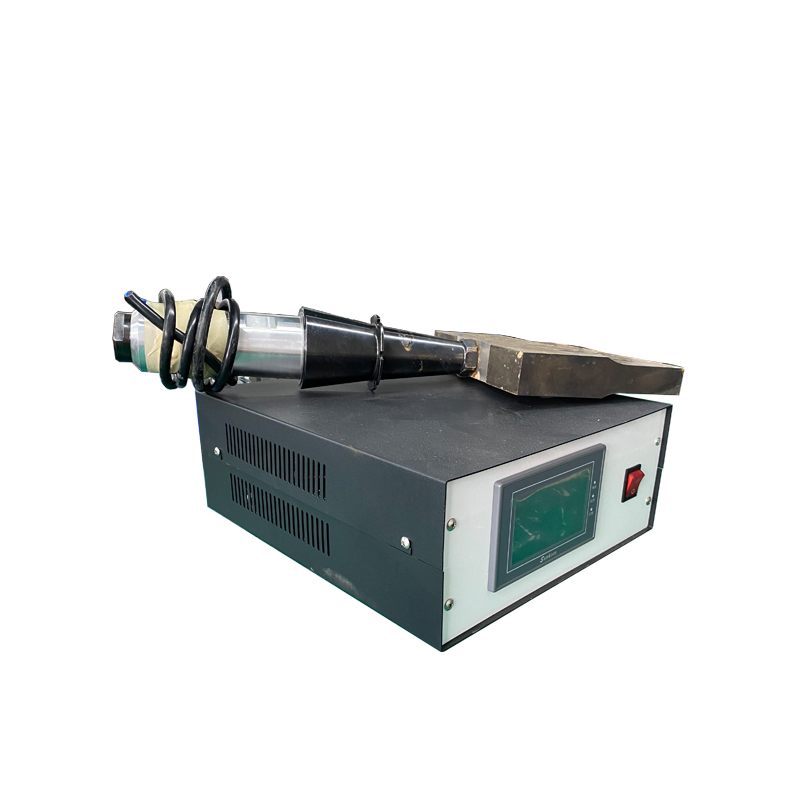

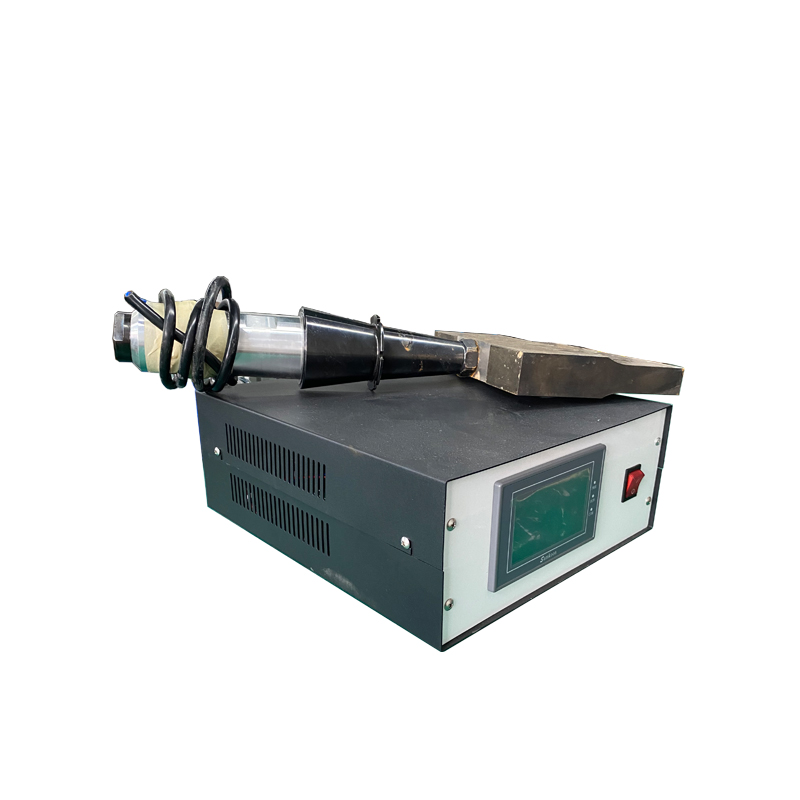

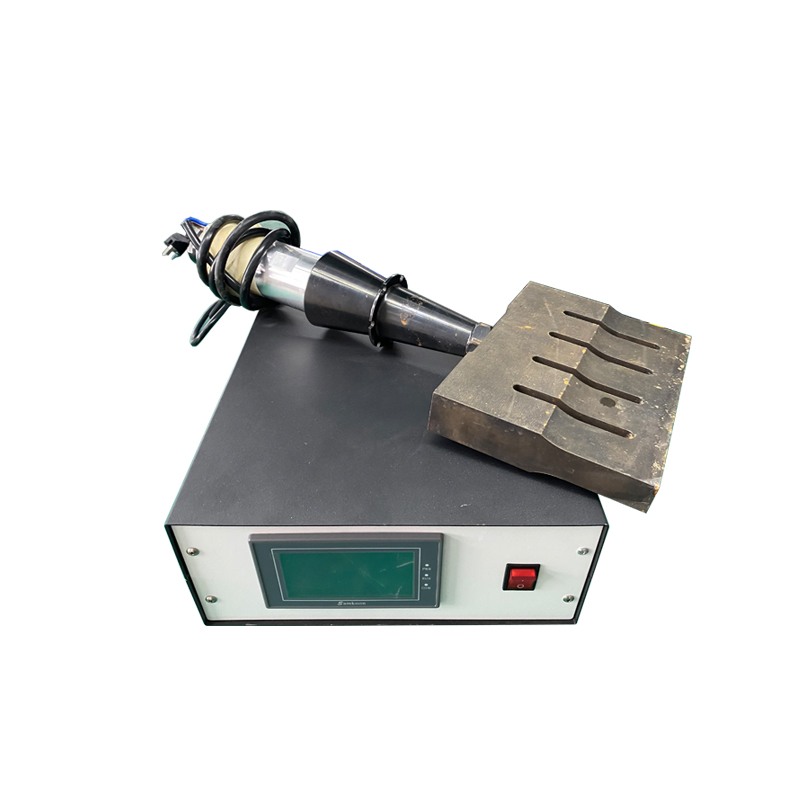

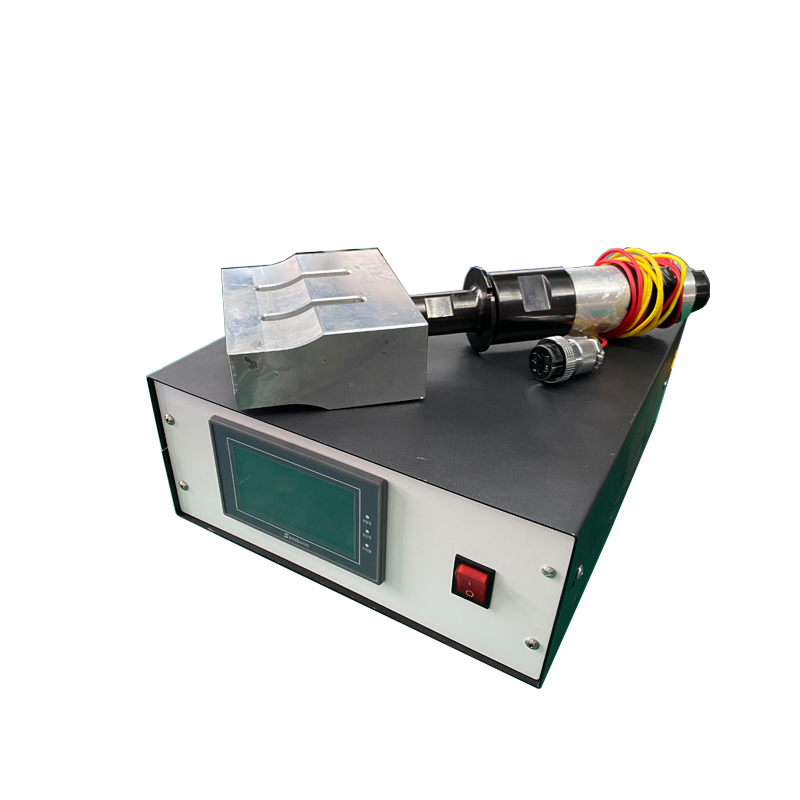

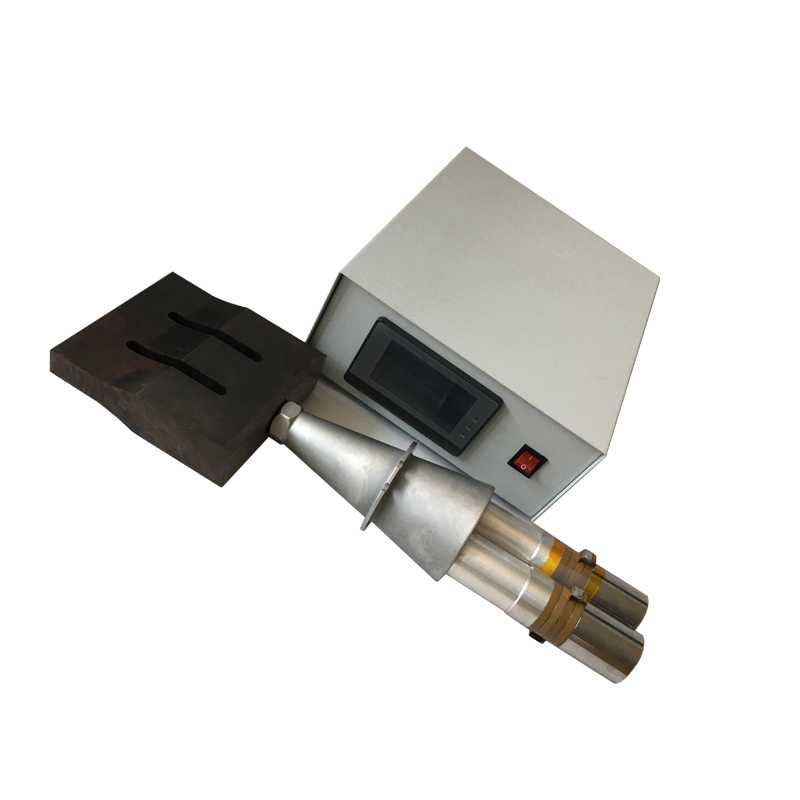

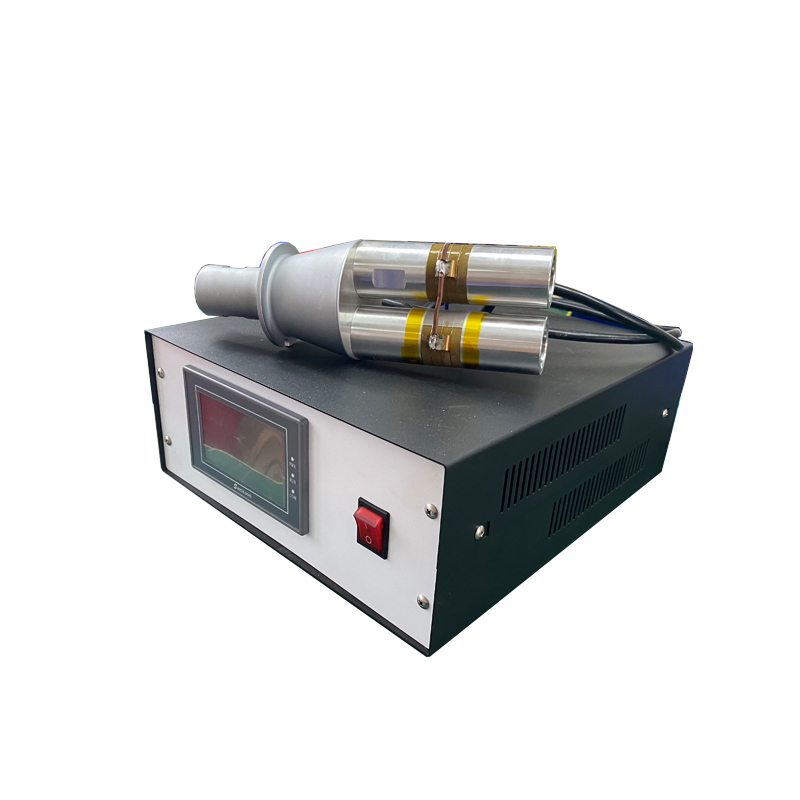

1500W Ultrasonic Welding Transducer Horn Plastic Ultrasonic Welding Generator Parts Aluminium Mold

1500W 15KHZ/20KHZ ultrasonic welding generator power supply During the welding process, due to the temperature, energy loss, welding area, welding head processing wear and other reasons of the welding load and ultrasonic acoustic system, the equivalent capacitance and resistance of the ultrasonic generator load will …

1500W Ultrasonic Welding Transducer Horn Plastic Ultrasonic Welding Generator Parts Aluminium Mold

1500W 15KHZ/20KHZ ultrasonic welding generator power supply During the welding process, due to the temperature, energy loss, welding area, welding head processing wear and other reasons of the welding load and ultrasonic acoustic system, the equivalent capacitance and resistance of the ultrasonic generator load will change with the work, which will cause the natural frequency of the ultrasonic acoustic system to drift. If the power frequency of the ultrasonic generator does not follow the change, It will cause the ultrasonic system to no longer work at the resonance point, reduce work efficiency, and exacerbate the loss of the transducer. Therefore, the ultrasonic generator must have a frequency tracking function to ensure that the frequency of the inverter trigger pulse in the ultrasonic generator follows the resonant frequency of the load.

The 1500W 15KHZ/20KHZ ultrasonic welding generator power supply uses a pid controller to calculate the step size of frequency change, mainly based on the fact that the resonance frequency of the ultrasonic system will increase to a certain extent as the ultrasonic generator changes with the load resistance. Therefore, the ultrasonic system has the largest working current when working at the resonance frequency. Therefore, the step size parameters can be adjusted according to the peak change relationship between the current and the frequency change.

The 1500W 15KHZ/20KHZ ultrasonic welding generator power supply can realize the frequency tracking function of the ultrasonic generator, so that the ultrasonic generator can follow the change of the equivalent capacitance and resistance of the ultrasonic generator load with the work, which will lead to the drift of the natural frequency of the ultrasonic acoustic system; The variable step frequency sweep controlled by a pid controller can quickly adjust the output frequency of the ultrasonic generator, enabling the entire ultrasonic system to quickly adjust to the resonant state and output maximum power. This variable step frequency sweep tracking control method reflects the advantages of fast real-time speed, simple electrical circuit, and easy cost implementation.

| Type | Full-length(mm) | Joint Bolt(mm) | Frequency(KHz) | Resonance Impedance(Ω) | Capacity(pF) | Input Power (W) |

| PLS-HJHNQ152600 | 153 | M20×1.5 | 15 | 15 | 13000 | 2600 |

| PLS-HJHNQ152000 | 167 | M20×1.5 | 15 | 10 | 9500 | 2000 |

| PLS-HJHNQ202000 | 128 | M18×1 | 20 | 10 | 11000 | 2000 |

| PLS-HJHNQ30500 | 77 | M10×1.5 | 30 | 5 | 5500 | 500 |

| PLS-HJHNQ28200 | 92.1 | M10×1 | 28 | 20 | 3000 | 200 |

| PLS-HJHNQ28100 | 91 | M8×1 | 28 | 25 | 2200 | 100 |

| PLS-HJHNQ28250 | 94 | 1/2-20 UNF | 28 | 20 | 4000 | 250 |

| PLS-HJHNQ202000 | 128 | 1/2-20 UNF | 20 | 10 | 20000 | 2000 |

| PLS-HJHNQ201500 | 124 | 1/2-20 UNF | 20 | 10 | 16000 | 1500 |

| PLS-HJHNQ38100 | 66 | M8×1.25 | 38 | 40 | 1200 | 100 |

| PLS-HJHNQ38200 | 65 | M8×1 | 38 | 14 | 3300 | 200 |

1500W Ultrasonic Welding Transducer Horn Plastic Ultrasonic Welding Generator Parts Aluminium Mold

标签:1500W 15KHZ/20KHZ ultrasonic welding generator power supply, 1500W Ultrasonic Welding Transducer Horn

Send Inquiry

20KHz 15KHz Ultrasonic Plastic Welding Generator With Transducer & Horn For Non-woven Welding Machine

20KHz 15KHz Ultrasonic Plastic Welding Generator With Transducer & Horn For Non-woven Welding Machine 1200W 20KHZ High Frequency Ultrasonic Plastic Welding Transducer And Generator For Metal Welding Machine

1200W 20KHZ High Frequency Ultrasonic Plastic Welding Transducer And Generator For Metal Welding Machine 1800W 20KHZ Low Power Ultrasonic Plastic Welding Transducer And Generator For Metal Welding System

1800W 20KHZ Low Power Ultrasonic Plastic Welding Transducer And Generator For Metal Welding System 20KHz 15KHz Ultrasonic Plastic Welding Generator With Transducer & Horn For Non-Woven Welding Machine

20KHz 15KHz Ultrasonic Plastic Welding Generator With Transducer & Horn For Non-Woven Welding Machine Ultrasonic Welding Machine Generator Transducer Horn With Different Types 15K 20K Plastic Welding Transducer

Ultrasonic Welding Machine Generator Transducer Horn With Different Types 15K 20K Plastic Welding Transducer Ultrasonic Nonwoven Welding Machine Ultrasonic Welding Generator And Ultrasonic Transducer Booster Horn

Ultrasonic Nonwoven Welding Machine Ultrasonic Welding Generator And Ultrasonic Transducer Booster Horn 1000W 20KHZ Piezoelectric Ultrasonic Plastic Welding Transducer And Generator For Metal Welding Machine

1000W 20KHZ Piezoelectric Ultrasonic Plastic Welding Transducer And Generator For Metal Welding Machine 20K 2000W 15K 2600W Ultrasonic Mask Earloop Making Welder Generator With Transducer For Ultrasound Welding Machine

20K 2000W 15K 2600W Ultrasonic Mask Earloop Making Welder Generator With Transducer For Ultrasound Welding Machine 3000W 20KHZ Ultrasonic Plastic Wleding Transducer Generator With Booster Horn For Ultrasonic Welding Machine

3000W 20KHZ Ultrasonic Plastic Wleding Transducer Generator With Booster Horn For Ultrasonic Welding Machine 3200W Ultrasonic Plastic Welder For N95 Face Welding Equipment With Generator Transducer Horn

3200W Ultrasonic Plastic Welder For N95 Face Welding Equipment With Generator Transducer Horn 2600W 15K Digital Ultrasonic Welding Machine For Mask With Ultrasonic Generator And Welding Transducer/Converter Horn

2600W 15K Digital Ultrasonic Welding Machine For Mask With Ultrasonic Generator And Welding Transducer/Converter Horn Plastic Welding Ultrasonic Generator Transducer Booster Horn For 15khz 20khz Ultrasonic Welding Machine

Plastic Welding Ultrasonic Generator Transducer Booster Horn For 15khz 20khz Ultrasonic Welding Machine