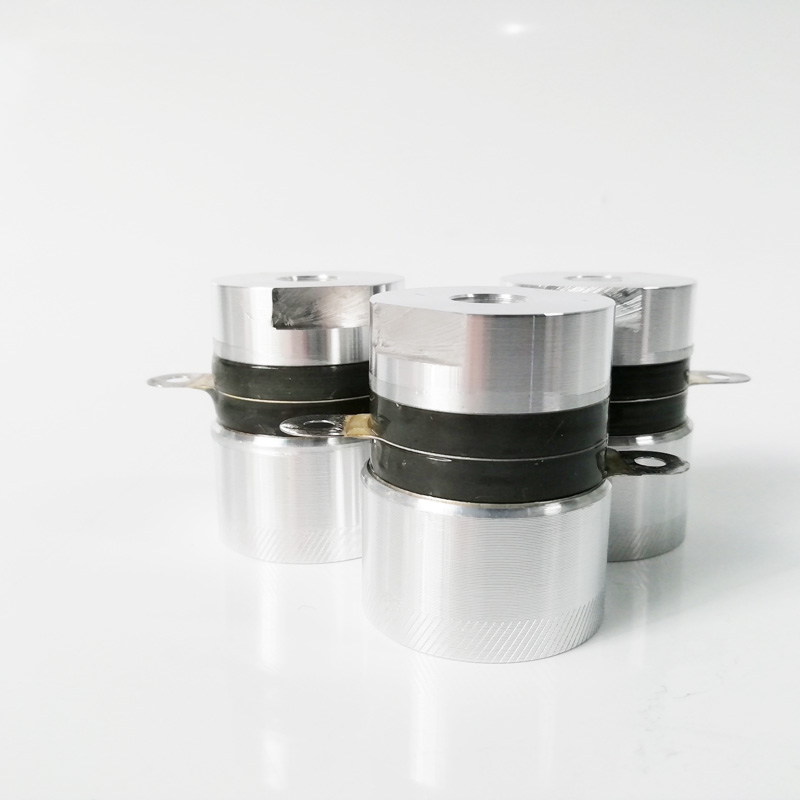

100K 60W PZT4 High Frequency Ultrasound Cleaner Transducer Piezoelectric Sensor Ultrasonic Cleaning Transducer

When ultrasonic transducer needs high power to remove dirt without considering the surface damage of the workpiece, it usually selects a lower cleaning frequency from 20kHz to 30kHz. The cleaning frequency within this frequency range is often used to clean large and heavy parts or high-density materials. High frequen…

When ultrasonic transducer needs high power to remove dirt without considering the surface damage of the workpiece, it usually selects a lower cleaning frequency from 20kHz to 30kHz. The cleaning frequency within this frequency range is often used to clean large and heavy parts or high-density materials. High frequency is usually used to clean smaller and finer parts, or to eliminate large particles. High frequency is also used for applications where damage to the surface of the workpiece is not allowed. The use of high-frequency can improve the cleaning function in several ways.

At present, there were two types of transducers in the market last time. One was a magnetic transducer made of nickel or nickel alloy; A piezoelectric transducer made of lead zirconate titanate or other ceramics.

When the ultrasonic transducer puts the piezoelectric data into the electric field with changing voltage, it will deform, which is the so-called “piezoelectric effect”. Absolutely speaking, magnetic transducers are made from data that deforms in a changing magnetic field. Regardless of the type of transducer used, the most fundamental factor is usually the intensity of the cavitation effect that occurs. Ultrasound, like other sound waves, is a series of pressure points, a wave that alternates between contraction and contraction. If the sound energy is strong enough, the liquid is pushed away during the contraction phase of the wave, resulting in bubbles; During the contraction phase of the wave, these bubbles burst or implode instantly in the liquid, producing a highly ineffective impact force, particularly suitable for cleaning.

As the frequency of ultrasonic waves in the cleaning machine increases and the number of cavitation bubbles increases, more and more dense shock waves occur, allowing them to enter smaller gaps. Persisting unchanged, the cavitation bubbles become smaller, and the energy released correspondingly increases, effectively reducing the damage to the surface of the workpiece. Another disadvantage of high frequency is that it reduces the viscous boundary layer, so that ultrasound can ‘detect’ the loss of very large particles.

| Type | Length(mm) | Weight(g) | Frequency(KHz) | Resonance Impedance (Ω) | Static Capacity (pF)±10% | Input Power(W) |

| PLS-QXHNQ20100 | 94 | 900 | 20 | 10-20 | 5200 | 100 |

| PLS-QXHNQ25100 | 77 | 710 | 25 | 10-20 | 6600 | 100 |

| PLS-QXHNQ28100 | 66 | 624 | 28 | 10-20 | 6600 | 100 |

| PLS-QXHNQ2560 | 77 | 530 | 25 | 10-20 | 5400 | 60 |

| PLS-QXHNQ2860 | 68 | 470 | 28 | 10-20 | 3800 | 60 |

| PLS-QXHNQ2850 | 82 | 425 | 28 | 10-20 | 4100 | 50 |

| PLS-QXHNQ3360 | 58 | 420 | 33 | 10-20 | 3800 | 60 |

| PLS-QXHNQ4060 | 56 | 310 | 40 | 10-20 | 5400 | 60 |

| PLS-QXHNQ4050 | 57 | 300 | 40 | 10-20 | 4100 | 50 |

| PLS-QXHNQ5435 | 36 | 135 | 54 | 10-20 | 3200 | 35 |

| PLS-QXHNQ6860 | 80 | 460 | 68 | 10-20 | 3800 | 60 |

| PLS-QXHNQ68120 | 67 | 588 | 68 | 10-20 | 7800 | 120 |

| PLS-QXHNQ8060 | 60 | 325 | 80 | 10-20 | 5400 | 60 |

| PLS-QXHNQ12060 | 56 | 260 | 120 | 10-20 | 5400 | 60 |

| PLS-QXHNQ13550 | 54 | 215 | 135 | 10-20 | 4200 | 50 |

标签:100K 60W PZT4 High Frequency Ultrasound Cleaner Transducer, High Frequency Ultrasound Cleaner Transducer, Piezoelectric Sensor Ultrasonic Cleaning Transducer

Send Inquiry

200KHZ 35W DIY High Frequency Ultrasonic Cleaner Transducer For Ultrasonic Cleaning System

200KHZ 35W DIY High Frequency Ultrasonic Cleaner Transducer For Ultrasonic Cleaning System 80khz 50W High Frequency Ultrasonic Transducer Micro Electronic Cleaner Vibrator For High Precision Parts Cleaning Machine

80khz 50W High Frequency Ultrasonic Transducer Micro Electronic Cleaner Vibrator For High Precision Parts Cleaning Machine 54khz Ultrasonic Cleaner Transducer For High Frequency Ultrasonic Cleaner Tank

54khz Ultrasonic Cleaner Transducer For High Frequency Ultrasonic Cleaner Tank 54KHZ 35W High Frequency Piezo Ultrasound Transducer Piezoelectric Ultrasonic Transducer

54KHZ 35W High Frequency Piezo Ultrasound Transducer Piezoelectric Ultrasonic Transducer 200KHZ 35W High Frequency Ultrasonic Transducer For Industrial Ultrasonic Cleaners Bath

200KHZ 35W High Frequency Ultrasonic Transducer For Industrial Ultrasonic Cleaners Bath 60khz 60W High Frequency Industrial Ultrasonic Transducer For Ultrasonic Cleaner

60khz 60W High Frequency Industrial Ultrasonic Transducer For Ultrasonic Cleaner 50KHZ 60W High Frequency Ultrasonic Transducer For Large Customized Ultrasound Cleaning Machine

50KHZ 60W High Frequency Ultrasonic Transducer For Large Customized Ultrasound Cleaning Machine High Frequency Piezoelectric Ultrasonic Transducer Ultrasonic Cleaner Transducer For Large Industrial Ultrasonic Cleaning Tanks

High Frequency Piezoelectric Ultrasonic Transducer Ultrasonic Cleaner Transducer For Large Industrial Ultrasonic Cleaning Tanks 100K 60W PZT4 High Frequency Ultrasound Cleaner Transducer Piezoelectric Sensor Ultrasonic Cleaning Transducer

100K 60W PZT4 High Frequency Ultrasound Cleaner Transducer Piezoelectric Sensor Ultrasonic Cleaning Transducer 50KHZ High Frequency Ultrasonic Cleaner Transducer For Industrial Ultrasonic Vibration Cleaner

50KHZ High Frequency Ultrasonic Cleaner Transducer For Industrial Ultrasonic Vibration Cleaner 54KHZ 35W High Frequency Ultrasonic Transducer For Stainless Steel Ultrasonic Cleaner Machine

54KHZ 35W High Frequency Ultrasonic Transducer For Stainless Steel Ultrasonic Cleaner Machine 120KHz High Frequency 50W Ultrasonic Piezoelectric Transducer Vibrating Part Medical Washing Machine

120KHz High Frequency 50W Ultrasonic Piezoelectric Transducer Vibrating Part Medical Washing Machine