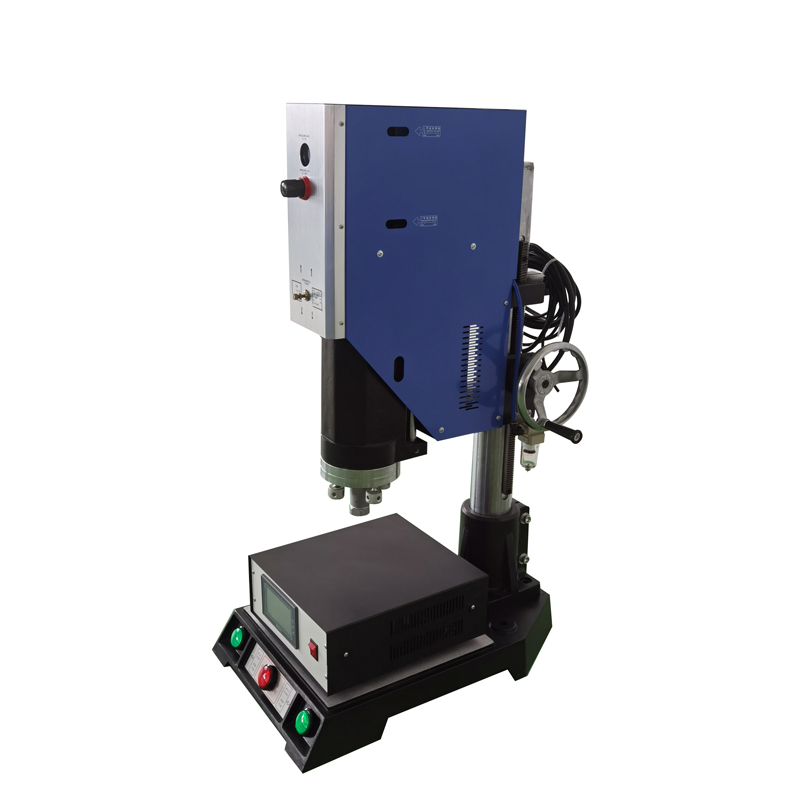

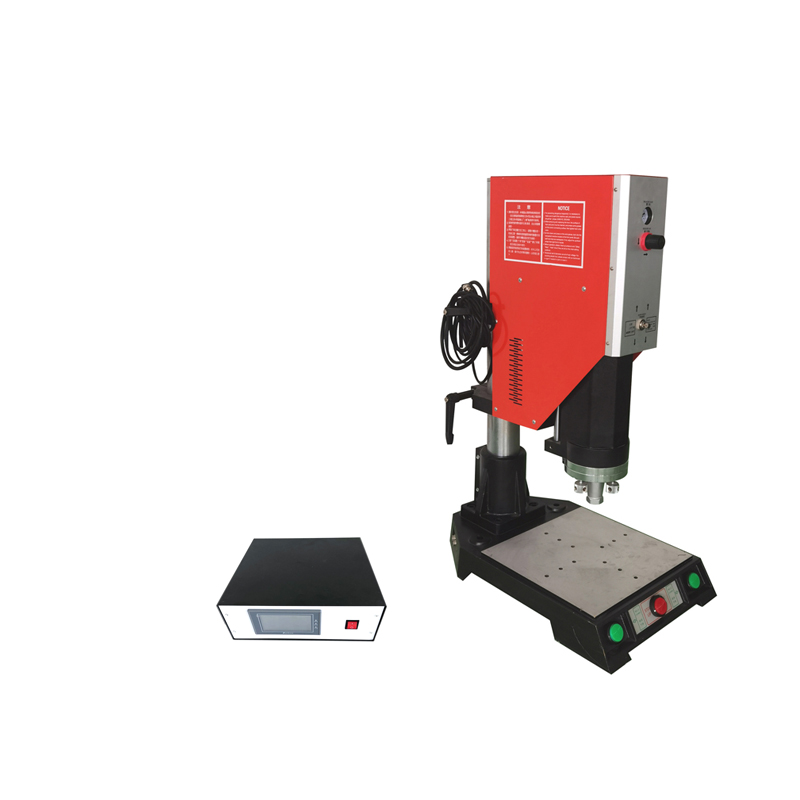

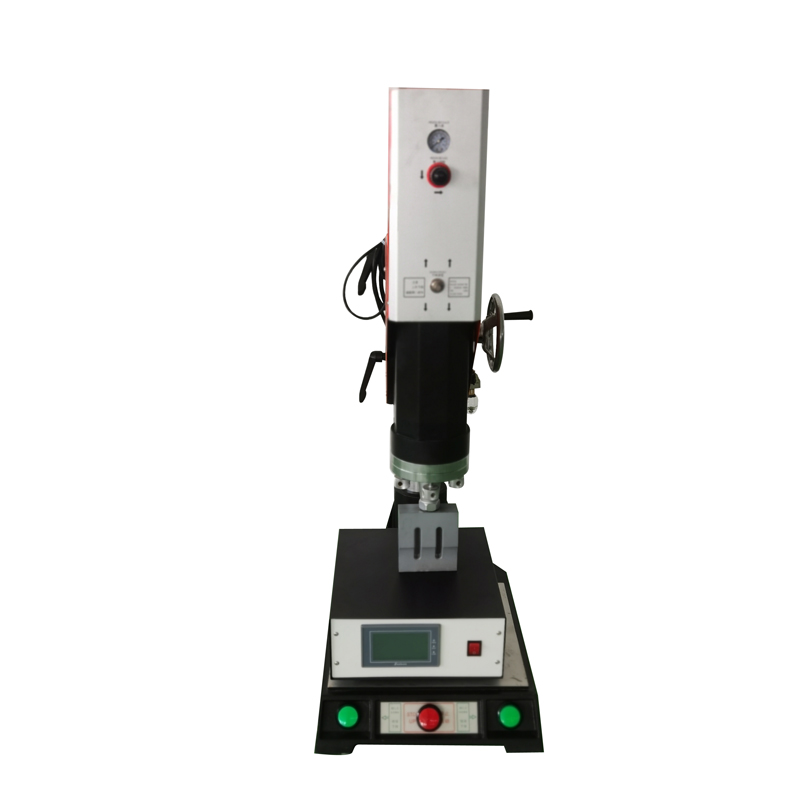

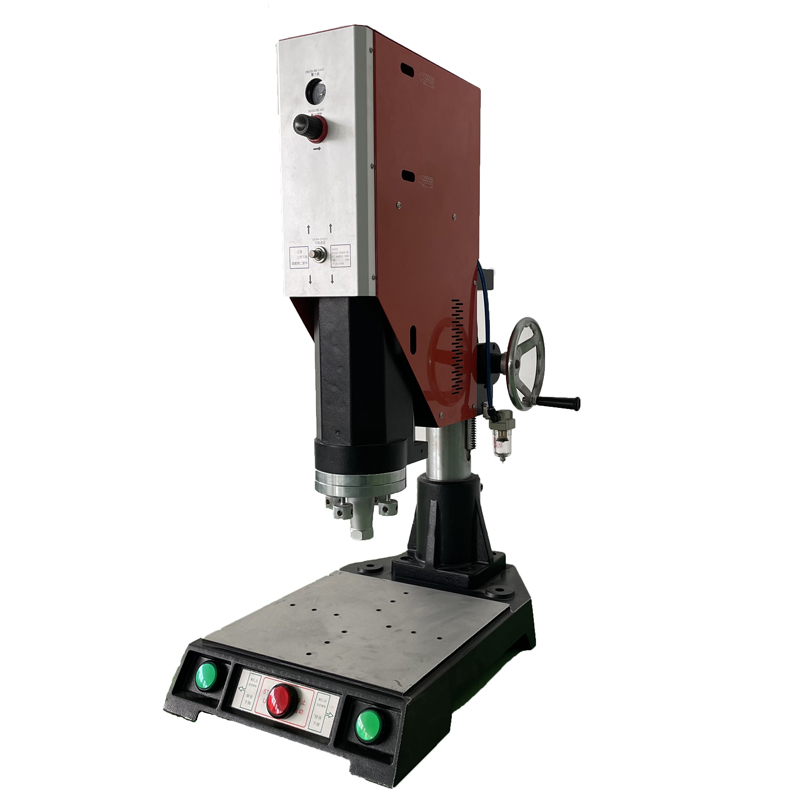

20khz Ultrasonic Plastic Welding Machine For Toys Plastic Body Parts/Car Plastic Element Welding Machine

Understanding the strength of ultrasonic welding operations cannot reach the strength of integrated molding, it can only be said to be close to the strength of integrated molding, and the required standards for welding strength must rely on multiple combinations. What are these combinations Plastic material: The resu…

Understanding the strength of ultrasonic welding operations cannot reach the strength of integrated molding, it can only be said to be close to the strength of integrated molding, and the required standards for welding strength must rely on multiple combinations. What are these combinations Plastic material: The result of ABS and ABS fusion is definitely stronger than that of ABS and PC fusion, because the melting point of two different materials will not be the same, and of course, the strength of fusion cannot be the same. Although we are exploring whether ABS and PC can be fused together? Our answer is that it is absolutely possible to weld, but is the strength after welding what we need? That’s not necessarily the case! And from another perspective, what about the situation where ABS melts with nylon, PP, and PE? If the ultrasound HORN instantly emits 150 degrees of thermal energy, although the ABS material has been melted, nylon, PP, and PE are only softened. We will continue to increase the welding parameters. At this point, nylon, PP, and PE have reached the ultrasonic fusion temperature, but the ABS material has been resolved to a different molecular structure!

When ultrasonic vibration is applied to plastic products, the surface of the product is prone to burns, and plastic columns or holes with thinner wall thickness within 1m/m are also prone to cracking. This is an inevitable prerequisite for the operation of ultrasonic plastic welding machines. On the other hand, due to the insufficient output energy of ultrasound waves (such as the extension and HORN upper model), it takes a long time to fuse the vibration friction energy into thermal energy, in order to accumulate thermal energy to compensate for the insufficient output power. This welding method does not achieve vibration friction heat energy in an instant, but relies on welding time to accumulate heat energy. Even if the melting point of plastic products reaches the fusion effect, it will cause the heat energy to stay on the surface of the product for too long, and the accumulated temperature and pressure will also cause burns, breakage, or rupture of the product. At this point, it is necessary to consider factors such as power output (number of segments), fusion time, dynamic pressure, and other coordination factors to overcome this lack of operation.

| Type | Power(W) | Frequency (KHz) |

| PU-UWM600W | 600W | 15KHZ/20KHZ/28KHZ/40KHZ |

| PU-UWM900W | 900W | 15KHZ/20KHZ/28KHZ/40KHZ |

| PU-UWM1000W | 1000W | 15KHZ/20KHZ/28KHZ/30KHZ |

| PU-UWM1500W | 1500W | 15KHZ/20KHZ |

| PU-UWM1800W | 1800W | 15KHZ/20KHZ |

| PU-UWM2000W | 2000W | 15KHZ/20KHZ |

| PU-UWM2600W | 2600W | 15KHZ |

| PU-UWM3200W | 3200W | 15KHZ |

| PU-UWM4200W | 4200W | 15KHZ |

标签:Ultrasonic Plastic Welding Machine For Toys Plastic Body Parts

Send Inquiry

Card Slab Ultrasonic Welding Machine 15k 20k 2600w Sports PSA Card Slabs Ultra Sonic Welder For Pokemon Card

Card Slab Ultrasonic Welding Machine 15k 20k 2600w Sports PSA Card Slabs Ultra Sonic Welder For Pokemon Card Automatic Ultrasonic Plastic Welder Plastic Welding Machine for Lead-Acid Battery Top Cover Welding Line

Automatic Ultrasonic Plastic Welder Plastic Welding Machine for Lead-Acid Battery Top Cover Welding Line Automatic Frequency Tracking 15K 2600W Ultrasonic Welding Machine for Plastic PSA Slabs Case ABS PP Welding Machine

Automatic Frequency Tracking 15K 2600W Ultrasonic Welding Machine for Plastic PSA Slabs Case ABS PP Welding Machine Ultrasonic Welding Machine Equipment Automatic Plastic Welding Acrylic Material Ultrasonic Plastic Bonding Machine

Ultrasonic Welding Machine Equipment Automatic Plastic Welding Acrylic Material Ultrasonic Plastic Bonding Machine 15khz 2600W Ultrasonic Sealing Plastic Welding Machine Popular Ultrasonic Plastic Welding Machine For Welding Auto Parts

15khz 2600W Ultrasonic Sealing Plastic Welding Machine Popular Ultrasonic Plastic Welding Machine For Welding Auto Parts Plastic Cards Case Ultrasonic Welder Sealer Ultrasonic Welding Machine For PSA / DNA Sports Grading Card Slabs

Plastic Cards Case Ultrasonic Welder Sealer Ultrasonic Welding Machine For PSA / DNA Sports Grading Card Slabs 3200W 15KHZ Ultrasonic Corrugated Plastic Box Welding Welder Machine With Waves Generator

3200W 15KHZ Ultrasonic Corrugated Plastic Box Welding Welder Machine With Waves Generator 20k 2600W Manual Acrylic Card Case Ultrasonic Welder Pokemon Grading Card PSA Slab Ultrasonic Plastic Welding Machine

20k 2600W Manual Acrylic Card Case Ultrasonic Welder Pokemon Grading Card PSA Slab Ultrasonic Plastic Welding Machine 2500W 20KHZ Automatic Welding Machine Welder Ultrasonic Spot Welder Ultrasonic Spot Welding Machine

2500W 20KHZ Automatic Welding Machine Welder Ultrasonic Spot Welder Ultrasonic Spot Welding Machine 1500W Precision Ultrasonic Plastic Welding Machine For Hard Plastic Material And Signal Generator

1500W Precision Ultrasonic Plastic Welding Machine For Hard Plastic Material And Signal Generator Ultrasonic Welder DNA PSA Sports Grading Card Slabs Plastic Ultrasonic Welding Sealer Machine With Digital Generator

Ultrasonic Welder DNA PSA Sports Grading Card Slabs Plastic Ultrasonic Welding Sealer Machine With Digital Generator Grading Card Coin Psa Slabs Ultrasonic Welding Machine Graded Card Slab

Grading Card Coin Psa Slabs Ultrasonic Welding Machine Graded Card Slab